Ijp v-2-n-3-page1-13-paper1-p03-11-rita moura fortes

-

Upload

universidade-anhembi-morumbi -

Category

Engineering

-

view

16 -

download

0

Transcript of Ijp v-2-n-3-page1-13-paper1-p03-11-rita moura fortes

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 1

THE USE OF MCT METHODOLOGY FOR RAPID CLASSIFICATION OF TROPICAL SOILS IN BRAZIL

Rita Moura Fortes * Professor of Civil Engineering and Head of Propaedeutic Studies of Engineering, Presbyterian University Mackenzie; Technical Director of LENC, São Paulo, Brazil * Rua Maranhão, 101 - apto 72, CEP 01240-001, São Paulo, Brazil [email protected] João Virgilio Merighi Professor and Head, Department of Civil Engineering, Presbyterian University Mackenzie, São Paulo, Brazil Consultant for the Department of Transportation, State of São Paulo, Brazil ABSTRACT: The construction of pavement structures and the reinforcement of subgrade soils must be preceded by accurate characterization of pavement materials and soils. The behavior of soils can vary from point to point, even if the soils have the same genetic origin. The drainage condition of the subsoil can modify the characteristics of its mechanical behavior. Thus, the success in the use of soils as a construction material requires a great number of laboratory tests, significant time, and adequate financial resources. These factors and low costs associated with abundantly available soil deposits allow the designers to optimize the management of highway construction projects. A rapid methodology for classifying tropical soils in accordance with the MCT (Miniature, Compacted, Tropical classification) is described to fill the gap in geotechnical investigation of soils used for road construction. This paper presents the MCT classification of tropical soils and practical examples of its use on highway construction projects in the state of São Paulo in Brazil. Considerable time and cost savings are achieved by implementing the rapid disk method of the MCT classification to characterize tropical soils. KEY WORDS: Highway, construction, tropical soils, lateritic soils, classification, MCT, disk method, visual 1. INTRODUCTION

1.1 Soils of Tropical Regions Soils that present abnormal properties as a result of the typical performance of geologic or pedologic processes of humid tropical regions are called tropical soils. Tropical soils are subject to a variety of climatic conditions, which warrant the need to appraise the genetic peculiarities of tropical soils. Two soils types are found in tropical regions: lateritic soils and saprolitic soils. Lateritic soils are found in upper layers, generally having red or yellow coloration due to the presence of aluminum hydroxides and ferric hydrates, are homogeneous, and are more resistant to erosion. Thickness of the upper layers are on the order of meters. This geologic process of disaggregation and decomposition is very slow and mostly active in the upper layers, which are drained and situated well above the water level. Saprolitic soils are formed due to decomposition of in situ rock underlying the lateritic soils and overlying the fresh parent rock. The decomposed rock is heterogeneous and not resistant to erosion. Thickness of the saprolitic layer is on the order of tens of meters. The saprolitic soil layer partially preserves some mineralogical and structural characteristics of the parent rock. Many times its anisotropy is due to stratification of the parent rock. Mica and kaolinite present in the silt soil fraction are responsible for the reduction of the plasticity index and increased liquid limit. The presence of predominant colors like purple, violet, blue, and light green is another peculiarity that allows the identification of saprolitic soil varieties. The use of tropical lateritic soils as a construction material for highways allows for a cost reduction of over 50% in costs associated with the subbase and base layers, or over 25% when the lateritic soil is treated with cement. However, not all types of tropical soils are suitable for use as a subbase or stabilized base. There are only certain types of lateritic soils having particular mechanical and hydraulic properties, which guarantee good performance and long life. With increased costs due to the long transportation distances and continued reductions in available

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 2

exploration and borrow areas of materials, it has become more difficult to find new deposits and justify their exploration. Associated with the difficulty in finding material deposits, there is an increase in testing costs, which adds to the total cost and extends project time. 1.2 Classification of Tropical Soils The most widely used soil classification system in the study of road construction materials is the American Association of State Highway and Transportation Officials (AASHTO) classification [1]. It is based on a classification system originally adopted by the United States Bureau of Public Roads in 1929, which rates soils through gradation, liquid limit, and plasticity index properties [2]. The Unified Soil Classification System (USCS), originally developed by Arthur Casagrande in the 1940’s and adapted by the American Society for Testing and Materials (ASTM), is more commonly used for geotechnical investigations of soils [3], rather than for the testing of soils used in highway projects. These traditional soil classification systems designed for cold and temperate climates show severe discrepancies in the expected geotechnical behavior of tropical soils. For example genetically distinct lateritic and saprolitic soils may receive the same classification but show different geotechnical behavior. A literature search of studies concerning soil identification and limitations when applied to tropical soils indicates that the MCT methodology [4,5] is the most appropriate test for classifying tropical soils. Traditional soil classifications, when applied to soils of tropical countries such as Brazil show a number of deviations with regard to the geotechnical performance of the tropical soil. Recognizing the difficulties and shortcomings detected in applying traditional soil classification methods, Nogami and Villibor [4,5] developed the MCT methodology of soil testing based mainly on mechanical and hydraulic properties of compacted tropical soils. This methodology is based on several test procedures, which accurately reproduce conditions of compacted tropical soil layers and their geotechnical characteristics that mirror the in situ behavior of tropical soils. Some of the reasons cited by Nogami and his colleagues [4,5] to develop the MCT method were: Limitations in traditional procedures to characterize and classify soils based on gradation and the Atterberg limits of Liquid Limit (LL) and Plasticity Index (PI). These index properties are insufficient to distinguish between the main types of tropical soils and their opposite features, such as lateritic and saprolitic soils, often mistakenly called “residual” soils in other countries. Experimental findings show good performance for pavement bases made of fine-grained lateritic soils (sifting nearly completely through the 0.42 mm sieve). On the other hand, traditional soil classification systems indicate that these soils are inappropriate for pavement bases. 1.3 Objectives and Scope of the Study The primary objective of this study is to describe a rapid test method for classifying tropical soils based on the MCT methodology. This method is implemented for geotechnical investigations of soils for highway projects in the state of São Paulo in Brazil. 2. MCT METHODOLOGY The MCT soil classification methodology uses small-sized (50-mm diameter) specimens compacted according to the adaptation of the United Kingdom Transportation and Road Research Laboratory (TRRL) procedure presented by Parsons [6], Parsons and Borden [7], and a new test called the mass lost by total immersion. This classification does not use the gradation, the liquid limit, and plasticity index as in the case of the traditional soil classification tests. This methodology includes the following two test groups: Mini CBR (California Bearing Ratio) and associated properties and Mini MCV (Moisture Condition Value) and associated properties. 2.1 Mini CBR Test Procedure In this procedure, similar to the CBR (California Bearing Ratio), but different because this test uses a small size (50 mm diameter) sample obtained though a compactation procedure called the mini Proctor. The molds have a diameter of 50 mm and a volume of 100 ml. The sample mass is 250g, and the maximum grain diameter is 2 mm. The diameter of the penetration piston (plunger) is 16 mm, while the loading machine has a capacity and

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 3

speed of 4.5 kN and 1.25 mm/min, respectively. There are two compactation rammers used for compaction: (a) standard energy rammer weighing 2.27 kg, height of drop 305 mm, blows ⎯ 10 total or 5 per side and (b) the intermediate energy rammer weighing 4.5 kg, height of drop 305 mm, blows ⎯ 12 total or 6 per side. Soaking time is 24 hours. If not soaked, expansion can be determined as in the CBR test. This test is used for pavement design as well as for choosing the soil to use in top subgrade layers, subbase layers, base layers, and shoulders. Through the mini CBR (shown in Table 1) and associated test properties one can obtain characteristics of soils appropriate for pavement bases. Usually, following compaction of specimens, several properties are established such as bearing ratio (Mini CBR), expansion, contraction, sorptivity, and permeability.

Table 1. Mini CBR test APPARATUS CHARACTERISTICS APPLICATION

S O IL

Similar to CBR (California Bearing Ratio) using of small-sized (50-mm diameter specimen), obtained through compaction procedure called mini Proctor. Molds: (50-mm diameter –100 ml volume of specimen) Samples: specimen weight 250 g; maximum diameter of grains 2 mm Compaction: standard energy (rammer weight 2.27 kg; height of drop 305 mm; blows (total) 10 (5 each side)); intermediate energy rammer weight 4.5 kg; height of drop 305 mm; blows (total) 12 (6 each side). Soaking time: 24 hours or without immersion and determine expansion similar to CBR test. Penetration piston (plunger): mini (16 mm diam.). Loading Machine: capacity 4.5 kN; speed 1.25 mm/min.

Used for design of pavements and selection of soils in tropical regions to use in subgrade layers, subbase layers, base layers and shoulders.

2.2 Mini MCV Test Procedure This test was developed by Nogami and Villibor in 1980 for tropicals soils and has been continually updated since that time [4,5]. The mini MCV test uses a small diameter (50 mm) sample. The mass of each sample (for establishing five points) is 200g and the maximum grain diameter is 2 mm. Each portion of the sample is compacted in a miniature compaction apparatus, allowing the measurement of the height of the potion inside the mold. The highest moisture content portion (moisture w1) is introduced it into the mold positioned in the way illustrated, pressing its top with the appropriate cylinder, before introducing the rammer (2.27 kg with 305 mm drop height). The first drop is made and the height A1 of the specimen is measured. The second drop is made and the height A2 is recorded. The test is continued making successive blows (while taking corresponding measurements of height) in the following series: 1, 2, 3, 4, 6, 8, 12, 16, …n, n + 1, … 4n. Successive blows are stopped when the difference in height between successive measurements becomes less than 0.1 mm, or when water expulsion is apparent on the top or bottom of the specimen, or the cumulative number of blows reaches 256. This procedure is a part of the MCT classification method to determine the classification of the soil, either lateritic or non-lateritic, and it is used to prepare samples for other tests of MCT methodology. The mass-lost-by-immersion test (Pi) is shown in Table 3. After mini MCV compaction, the specimen is partially extruded from the mold, so that a 10-mm long portion becomes salient. The mold and specimen are positioned horizontally in a tank which is filled with water until the water level reaches at least 10 mm above the mold. The behavior of the specimen is observed during the first few hours. At least 12 hours later the fallen part is collected and its dry mass and the mass lost by total immersion are determined. The mini MCV and associated tests (shown in Tables 2 and 3) provide parameters to determine the “c’ ” and “e’ ” coefficients which are used to rate tropical soils according to the MCT methodology, in addition to the determination of all other properties mentioned in the Mini CBR and associated test.

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 4

Table 2. Compaction test - Mini MCV APPARATUS CHARACTERISTICS APPLICATION

MINI PROCTOR: Variable moisture condition and energy. The energy corresponding Proctor energy. MINI MCV: variable moisture condition and energy, moistened sample for compaction is 200 g (mini) and 30 g (Sub mini). The compaction procedure is similar to the one proposed by Parsons in 1976 [6] and Parsons and Borden in 1979 [7]. Each portion is compacted in a miniature compaction apparatus, allowing the height of the sample inside the mold to be measured. The highest moisture content portion (moisture w1) is introduced it into the mold positioned as illustrated, pressing gently at its top with the appropriate cylinder, before introducing the rammer. After the first drop, the height A1 of the specimen is measured. Make the second drop and record the height A2, and repeat for successive blows taking measurements of height, following the series proposed by Parsons: 1, 2, 3, 4, 6, 8, 12, 16, …n, n + 1, … 4n. Stop to make a successive blow when the difference in height between successive measurements is less than 0.1 mm, or when water expulsion is apparent at the top or bottom of the specimen, or the number of blows reaches 256.

Sample preparation for tests using MCT methodology. This procedure is a part of MCT classification method. Obtained at maximum density for various moisture contents (variation in compaction energy).

Table 3. The mass-lost-by-immersion test (Pi)

APPARATUS PROCEDURE APPLICATION

After mini MCV compaction, the specimen is partially extruded from the mold, so that a part 10 mm long becomes salient. The mold with specimen is positioned horizontally in a tank, which is flooded until the water level is at least 10 mm above the mold. The behavior of the specimen is observed during the first few hours. At least 12 hours later the fallen part is collected and its dry weight and mass lost by total immersion is determined. [3,4,5]

A part of MCT classification methodology. Determines the behavior of the soil: lateritic or non-lateritic Erosion resistance.

The properties obtained through the mini CBR and associated tests are determined on specimens compacted at constant energy, equivalent to normal and intermediate levels at several moisture contents. For the mini MCV (shown in Table 2) and associated tests, with the exception of the mass-lost-by-immersion test (Table 3), soil properties are obtained at maximum density for various moisture contents (reflecting variations in the compaction energy). Nogami and Villibor [4,5] proposed the mini MCV test as a part of the MCT classification method. The MCT methodology aims at grouping tropical soils according to their behavioral peculiarities from the mechanical-hydraulic point of view. However, to identify these soil groups quickly in the field, the methodology lacked a rapid consolidated procedure such as that developed by Casagrande for other soils [3]. Nogami and Cozzolino started the development of the “disk method” in 1985 [8]. Fortes in 1990 [9] and Fortes and Nogami in 1991 [10] submitted a proposal for a trial and identification procedure of MCT groups using simple equipment to produce a number of quick and straightforward calculations based on empirical indices and qualitative values. This procedure can be carried out in the field at a low cost and identifies lateritic and non-lateritic behavior according to the MCT classification groups [9,10].

DIAL

RAMMER

MOLD

FEET OF RAMMER

SPECIMEN

BASE

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 5

ASSOCIATED TESTS MINI CBR

EXPANSION, CONTRACTION, SORPTIVITY TEST, PERMEABILITY

COMPACTION TEST

MINI PROCTOR

GROUP OF TESTS MINI CBR AND

ASSOCIATED TESTS

THE MASS LOST BY TOTAL IMMERSION

COMPACTION TEST

MINI MCV

GROUP OF TESTS MINI MCV AND ASSOCIATED

TESTS

DYNAMIC PENETROMETER

MINI CBR

CONVENTIONAL

MINI MCV

MOISTURE CONDITION

GROUP OF TEST “IN

SITU” TESTS

MCT

METHODOLOGY

Figure 1. Test groups of the MCT methodology [14] 3. MCT CLASSIFICATION OF TROPICAL SOILS

3.1 Overview and Example Applications of MCT Classification The MCT methodology derives from the practice of using small specimens (50 mm in diameter) of compacted tropical soils. Figure 1 shows a schematic of the MCT methodology as described by Villibor et al. [14]. The MCT classification separates tropical soils into classes of: (1) lateritic behavior and (2) non-lateritic behavior. The lateritic and saprolitic soils, according to the MCT classification, can belong to the following groups of lateritic behavior, assigned by letter L, being subdivided in 3 groups: LA – lateritic quartzous sand; LA’ - lateritic sandy, from arena; and LG’ – lateritic clayey from argila. Non-lateritic behavior (saprolitic) soils, assigned by letter N, are subdivided in 4 groups: NA non-lateritic sand, silts and mixtures and silts with predominance of quartz grain and/or mica; NA’ quartzous sandy with fine or non-lateritic behavior (alone arena); NS’ non lateritic silt, and NG’ non-lateritic clayey. To classify lateritic and saprolitic soils through the MCT Methodology, the graph of Figure 2 is used. The dashed line separates soils of lateritic behavior from the soils of non-lateritic behavior. The mechanical and hydraulic behavior of the soil can be estimated using Table 4. Nogami and Cozzolino [8] considered a quick procedure in view of the necessity of rapid tropical soil identification in the field. Fortes [9] and Fortes and Nogami [10] presented a proposal for an easy procedure to identify MCT groups that corresponded to a series of fast and simple determinations, based on empirical indices and qualitative determination, using simple equipment in the field. This low-cost method differentiates between soils of lateritic and non-lateritic behavior as MCT classifications.

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 6

Figure 2. Graph of MCT soil classifications [11]

Table 4. Properties and relative desirability in transportation applications based on MCT soil classification

groups [11]

(1) Specimens compacted near the maximum dry density and optimum moisture using standard compaction effort 3.2 Development of Rapid “Disk Method”

BEHAVIOR N = NON-LATERITIC L = LATERITIC MCT GROUP NA NA’ NS’ NG’ LA LA’ LG’

PROPERTIES (1)

V = VERY HIGH H = HIGH M = MEDIUM L = LOW

NOT SOAKED MINI-CBR SOAKED

M, H

M, H

H

M, H

M, H

L, M

H

L

H

H

V, H

H

H

H EXPANSION L L H M, H L L L SHRINKAGE L L, M M M, H L L, M M, H PERMEABILITY (K) M, H L L, M L, M L, M L L SORPTIVITY (s) H L, M H M, H L L L

RELATIVE DESIRABILITY AS: n = NOT SUITABLE

PAVEMENT BASE N 4th n n 2nd 1st 3rd SELECT SUBGRADE 4th 5th n n 2nd 1st 3rd COMPACTED SUBGRADE 4th 5th 7th 6th 2nd 1st 3rd EMBANKMENT (CORE) 4th 5th 6th 7th 2nd 1st 3rd EMBANKMENT (SHELL) N 3rd n n n 2nd 1st EARTH ROAD SURFACING 5th 3rd n n 4th 1st 2nd

CLASSIFICATION OBTAINED FROM

TRADITIONAL INDEX

PROPERTIES

USCS/ASTM

SP

SM

SM SC ML

SM, CL ML MH

MH CH

SP

SC

SC

MH ML CH

AASHTO

A-2 A-2 A-4 A-7

A-4 A-5 A-7

A-6 A-7-5 A-7-6

A-2

A-2 A-4

A-6 A-7-5

L = LATERITICN = NON-LATERITICA = SANDA’ = SANDYS’ = SILTYG’ = CLAY

1.00

0.50

2.00

1.75

1.50

1.15

0.5 0.7 2.01.71.51.0 3.02.50.0Coefficient c’

Inde

x e

’0.27 Coefficient c’0.5 0.7

L = LATERITICN = NON-LATERITICA = SANDA’ = SANDYS’ = SILTYG’ = CLAY

L = LATERITICN = NON-LATERITICA = SANDA’ = SANDYS’ = SILTYG’ = CLAY

1.00

0.50

2.00

1.75

1.50

1.151.00

0.50

2.00

1.75

1.50

1.15

0.5 0.7 2.01.71.51.0 3.02.50.0Coefficient c’

0.5 0.7 2.01.71.51.0 3.02.50.0Coefficient c’

Inde

x e

’0.27 Coefficient c’0.5 0.70.27 Coefficient c’0.5 0.7

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 7

Nogami and Villibor in 1994 and 1996 [11,12,13] and Villibor et al. in 2000 [14] presented simplifications to identify MCT groups through a graph of the diametrical contraction (shrinkage) versus the penetration values. The method is based on the fabrication of small disks of soil (20-mm diameter) that are molded in stainless steel rings and dried. After drying, the diametrical contraction of the inserts cast in stainless steel rings is measured. The inserts are then submitted to a sorptivity test, which makes it possible to see cracking, expansion activity, and resistance to the penetration of a standard needle. A mini penetrometer is used to determine the shrinkage and consistency after soaking dried specimens in water. In 1997, Fortes presented a proposal to standardize this rapid disk procedure at the conference of the First Permanent Chamber of Occurred Technological Development in the Presbyterian University Mackenzie [15]. The proposed disk method for rapid identification has been standardized by the Department of Transportation of the State of São Paulo (DER-SP) in Brazil and has been successfully used in several recent highway projects. The “Cost-Effective Paving Program” developed by NOVACAP (NOVA CAPITAL, the new capital city of the federal district in Brazil) has adopted this procedure during the feasibility study and executive planning stages as a strategy to cut costs and provide alternative cost-effective paving solutions for the satellite cities in Brazil. Currently the procedure is being used as a preliminary geotechnical investigation tool by DER-SP in a construction project to double a 120 km extension of the Raposo Tavares highway – SP 270, known as Assis-Prudente [16].

4. DISK METHOD FOR RAPID IDENTIFICATION OF TROPICAL SOILS The detailed description of the inexpensive and simple disk method of rapid soil identification is presented. This method was developed for highway applications using the MCT tropical soil classification methodology based on a simple manual-visual examination. 4.1 Definitions and Conventions

(a) Contraction (Ct) is the diametrical contraction of the disk or shrinkage, expressed in mm, with a precision of 0.1 mm.

(b) Penetration is the measure of penetration of the point near the confined border and in the center using one standard mini penetrometer, expressed in mm, with a precision of 0.1 mm.

(c) Fissures appear on the top of the specimen after a 2-hour soaking of the specimen. (d) Expansion is the increase in the diameter of the test specimen measured after soaking.

4.2 Apparatus and Materials In addition to the usual soils laboratory equipment, the following devices are used for the accomplishment of this quick test:

(1) Stainless steel rings with internal diameter of 20 ± 0.05 mm, 5 mm high, and 3-mm wall thickness. (2) Porous stones having a thickness of 5 mm and permeability of about 10-2 cm/s, capable of maintaining a

negative pressure of 5 mm water column again its exterior surface as seen in Figure 3. (3) Devices for measuring contraction with a precision of 0.1 mm. A magnifying lens is useful. (4) Flexible spatula with a blade about 80 x 20 mm. (5) A device to dry the specimens at a maximum temperature of approximately 60º C. (6) Sieves of 2.00 mm and 0.42 mm. (7) A scale graduated in millimeters. (8) A mini penetrometer with a uniform 1.3 mm diameter cylindrical shaped flat end having a total mass of

10 g. A universal penetrometer for asphalt penetration tests with the necessary adaptors can be used. (9) Filter papers and a ground glass plate measuring about 100 x 100 x 4 mm. These are similar to those

used for determination of traditional soil index values of Plastic Limit (PL) and PI. Figure 4 (a) shows the equipment used.

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 8

Figure 3. Device for soaking specimen 4.3 Test Procedure (a) Calibration: The plate of porous rock must be clean, saturated, and level, with negative pressure applied as

described in item 4.2. (b) Sample preparation: Dry the collected sample in air and crush the aggregates in a mortar with a rubber-

covered pestle. Get at least 30 ml or 50 grams of the sample fraction that passes the 0.42 mm sieve. Humidify the sample fraction that passes the 0.42 mm sieve in capsule stanches and leave it to rest for a minimum of 8 hours.

(c) Test steps: (c.1) Mixing: Mix the sample thoroughly with a spatula over a glass plate, either adding water drops or

drying as required until its thickness is exactly 1 mm. This step is shown in Figure 4 (b). In non-lateritic sands, silts, or clayey soils, thoroughly mixing 100 times with a spatula is enough. In clayey or sand lateritic soils, the mixing may be very intense, requiring about 400 times with the spatula. After completion of mixing, determine the consistency of the sample using a mini penetrometer.

(c.2) Molding and drying of the specimen: Get a small spheroid (diameter of about 10 mm) of the sample

that was previously mixed and reached the consistency of a 1-mm penetration. Put the spheroid inside the ring, and press it with the thumb against a ring horizontally displayed on a Teflon sheet. In the case of very sticky soils, use a horizontal flat surface covered with a thin PVC film or another material to prevent adherence of the soil to the border of the ring. Cut the excess material using a wire trimmer. While finishing the cutting operation, if you observe depression in any of its two faces then repeat the operation until as much of the exterior face of the interior of the ring of soil is filled by the mixture, as shown in Figure 4 (c). Hold the filled rings with an appropriate support to keep them in a vertical position, and place them to dry at a maximum temperature of 60º C for at least 6 hours. They can be left to dry in the surrounding air, but the drying time must be at least 12 hours.

(c.3) Shrinkage measurement: Cool the joint ring-specimens for about 15 minutes if they were dried in a

greenhouse. Place the specimens on a plain, horizontal surface. Measure the shrinkage (or diametrical contraction) using the precision millimeter scale with the aid of a magnifying lens, repeating the measurement at three different points on the disk at 120º angular displacements. See an illustration in Figure 4 (d).

(c.4) Soaking and penetration measurement: Transfer the ring with the respective disk to a porous plate

saturated and covered by a paper filter. This is shown in Figure 4 (e). Let it rest about two hours. Mark and note if the tablet shows fissures or expansion of its exterior surface. See examples in Figures 4 (f), (g), (h), and (i). Measure the penetration of the disks using with a standard mini penetrometer, as shown in Figures 4 (j) and (k). Leave the penetrometer tip on the surface of the central area of the disk or separate blocks containing fissures, freeing it to penetrate in a vertical line, and allowing a free fall. Conduct at least three tests for each disk.

Item Description A1 Water A2 Porous stone A3 Filter paper A4 Plate A5 Rings - diameter of 20 mm, height of 5 mm

5 mm A1

A3 A5 A2

A4

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 9

Figure 4. Disk Method: (a) equipment, (b) thorough mixing with the spatula, (c) molding of the disks, (d)

measurement of the shrinkage, (e), (f), and (g) sorptivity, (h) and (i) expansion, (j) and (k) penetration

Figure 5. Chart for tropical soil classification by the disk method [13]

(a) (b) (c)

(d) (e) ( j )

(f) (g)

( h )

( i ) (k)

0.2 0.5 0.9 1.3 1.7

01

23

4

5

0.15 0.22 0.55 0.90 1.40

LA – LA’ LA’ – LG’

LA

LA’ LG’

NS’ – NG’NS’ / NA’NS’ – NA’NA – NS’

NA’NA’ / NS’ NA’ / NS’ NG’

(NG’–NS’)

Diametrical Contraction or Shrinkage Measurement (mm)

Coefficient c’

Pene

trat

ion

(mm

) NA

0.2 0.5 0.9 1.3 1.7

01

23

4

5

0.15 0.22 0.55 0.90 1.40

LA – LA’ LA’ – LG’

LA

LA’ LG’

NS’ – NG’NS’ / NA’NS’ – NA’NA – NS’

NA’ / NS’ NA’ / NS’ NG’

(NG’–NS’)

Diametrical Contraction or Shrinkage Measurement (mm)

Coefficient c’

Pene

trat

ion

(mm

) NA

0.2 0.5 0.9 1.3 1.7

01

23

4

5

0.15 0.22 0.55 0.90 1.40

LA – LA’ LA’ – LG’

LA

LA’ LG’

NS’ – NG’NS’ / NA’NS’ – NA’NA – NS’

NA’NA’ / NS’ NA’ / NS’ NG’

(NG’–NS’)

Diametrical Contraction or Shrinkage Measurement (mm)

Coefficient c’

Pene

trat

ion

(mm

) NA

0.2 0.5 0.9 1.3 1.7

01

23

4

5

0.15 0.22 0.55 0.90 1.40

LA – LA’ LA’ – LG’

LA

LA’ LG’

NS’ – NG’NS’ / NA’NS’ – NA’NA – NS’

NA’ / NS’ NA’ / NS’ NG’

(NG’–NS’)

Diametrical Contraction or Shrinkage Measurement (mm)

Coefficient c’

Pene

trat

ion

(mm

) NA

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 10

4.4 Results

a) Contraction (Ct) is the diametrical contraction of disk of soil (or shrinkage) after drying, expressed in mm, with a precision of 0.1 mm.

b) Penetration is the measure for penetration of the point next to the confined border using the standard mini penetrometer, expressed in mm, with a precision of 0.1 mm.

c) The value of coefficient c’ can be read directly from the graph showing the disk method classification developed by Nogami and Villibor [13] and presented in Figure 5.

4.5 Soil Classification The measurements of the diametrical contraction or shrinkage and the penetration are used with the tropical soil classification chart in Figure 5 to assign the tropical soil group letter according to the MCT methodology. 4.6 Complementary Determination The rapid disk test must be repeated when the values of penetration measured in the test specimen and the sorptivity are close to or equal 2 mm. This implies that the results correspond to samples, which are close to the line that separates lateritic soil groups (prefix L) from the non-lateritic soil groups (prefix N) in the MCT classification graph. The rapid test must be repeated by applying pressure in the disk mold with the aid of a small rigid plate and a piece of thick filter paper. The new measurements are adopted for the preliminary classification of tropical soils. 5. COMPARISON OF RESULTS FROM THE RAPID DISK METHOD AND THE TRADITIONAL MCT METHODOLOGY Table 5 presents the results of 34 samples using the new rapid disk test method and the traditional MCT methodology [16]. It is observed that the classification discrepancies are more representative for the sand soils, which show non-lateritic behavior and similar properties. Most of the results are consistent considering that the disk method is used for preliminary soil identification using the MCT classification.

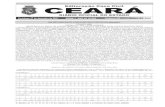

Table 5. Correlation between traditional MCT classification and rapid disk method identification [16]

Sample Traditional MCT

Classification

Rapid MCT Classification

by Disk Method18 LA’ LA’/LG’ 19 LG’ LG’ 20 LA’ LG’ 21 LG’ LG’ 22 LA’/NA’ NA 23 LA’ NA/LA 24 NA NA 25 LG’ LG’ 26 LG’ LG’ 27 NA NA 28 LA’ LG’ 29 NA NA 30 NS’/NA’ NA/NS’ 31 NA’ NA/NS’ 32 NS’/NA’ NA/NS’ 33 NS’ NS’/NA’ 34 NA’/NS’ NA/NS’

Sample Traditional MCT

Classification

Rapid MCT Classification

by Disk Method01 LA'/LG' LA' 02 LA'/LG' LA'/LG' 03 LA' LA' 04 LG' LA' 05 LG' LA'/LG' 06 LA' LA' 07 LG' LA'/LG' 08 LG' LA'/LG' 09 LA' LA/LA' 10 LA' LA/LA' 11 LA' LA' 12 LG' LG' 13 LA'/LG' LA'/LG' 14 LA'/LG' LA'/LG' 15 NS' NA/NS'LA'/LG' 16 NA'/NG'LA'/LG' NG' 17 NA' NA/NS'LA'/LG'

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 11

6. THE BR-0295 HIGHWAY MAINTENANCE PROGRAM The Government of the State of São Paulo, desiring to improve the traffic and security conditions for the 20,000 km network of roads under its jurisdiction and consequently increase the efficiency of the production sectors and reduce transport costs, planned a comprehensive program of maintenance for approximately 1,200 km of roads under the jurisdiction of DER-SP [17]. The maintenance consists of the following phases: rehabilitation, restoration, and reconstruction. For the implementation of this program, the Government of the State of São Paulo requested financial support from the Inter-American Bank of Development (BID). The expected total investment is US$ 240 million, consisting of US$ 120 million financed by BID and US$ 120 million by the State treasury. The road maintenance program, conceived with an integrated approach, involved the following topics: a) Maintenance of the selected roads: rehabilitation, restoration, or reconstruction of the selected roads;

implementation of pavement shoulders; construction of intersections; and restoration or reconstruction of bridges and drainage structures.

b) Improvements in the condition of road safety: implementation of a third traffic lane of traffic; adjustments to

road geometry; implementation of areas for bus stops, bike lanes, and central islands; and rehabilitation of the horizontal and vertical alignments.

c) Rehabilitation of the corridor environment: involving slope stabilization; soil deposits; old areas of support

to the workmanship (seedbeds, deposits, plant, etc.); replacement of the vegetation covering the degraded areas; and rehabilitation of the areas where soil erosion occurred that posed risks to adjacent areas.

The first phase of this project had 23 lots with a total of about 1,200 km in the State of São Paulo, which were approved in January of 2002 and 704 km of construction initiated in January of 2003. The second phase of the program includes 465 km of roads divided into 15 lots, which were initiated in July of 2002 completed in July of 2003. In the geotechnical investigation proposal presented in the Public Bid CO 010, studies of the soil deposits were foreseen. These studies were intended so that the existing soil deposits could be used as a reinforcing subgrade layer as well as for subbase and base layers, either stabilized with cement or used with no stabilization. Some adjustments were made to the long phase 1 program, considering the distances between the roads and the respective deposits of materials, locations of the test laboratories, the necessary time for the accomplishment of the tests, and the financial constraints. The program adjustments were later standardized for the project for doubling SP 270 in phase 2 of the same program. Initially, the AASHTO soil classification was used in geotechnical studies. However, due to the peculiarities described previously, the studies of the soil deposits were modified using the rapid MCT classification by the disk method. In the field, the soils in areas with potential for use as a structural pavement layer, a sieve of 50-mm mesh is used, and a test is made for each sample removed from one corner of the quadrilateral. Samples of 1 m x 1 m are collected in the field since the material does not have variations in the texture and color. The rapid disk method is executed at about 40% of the cost of a complete traditional MCT classification procedure. When the soil deposits are identified for potential use as materials of construction, more samples are selected to conduct complete MCT classification tests. By the end of the year 2003, tests will be completed for the first inter-laboratory program. Since 1995 the MCT test has been added to the list of standard tests for inter-laboratory test programs developed in Brazil.

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 12

7. CONCLUDING REMARKS This paper presents the MCT classification of tropical soils and practical examples of its use on highway construction projects. These highway projects consist of over 1,200 km of rehabilitation/reconstruction and the construction of a third highway lane in the state of São Paulo, Brazil. The use of the rapid MCT classification test has been successful in the western region of the state of São Paulo where thick layers of lateritic soils are found adjacent to non-lateritic soils, making it difficult to distinguish between the soils based on color and the visual guidelines typically used for tropical soils. For the study of soil material deposits, the rapid disk method of MCT classification offers lower costs and less time than complete traditional MCT classification tests. It is essential to use a representative sample, since the amount of soil necessary to perform the rapid MCT classification test is small. In case of doubt, one proceeds in accordance with the complete traditional MCT methodology. ACKNOWLEDGEMENT: The authors thank Job Shuji Nogami of the Laboratory of Pavement Technology of the Polytechnic School of the University of São Paulo (LTP-EPUSP) for his contributions to the disk method for rapid MCT classification and to the standardization process. Thanks are also due to the staff of LENC - Laboratório de Engenharia e Consultoria S/C Ltda, particularly to the head of the laboratory, Benício Bibiano Bento for conducting the tests reported in this paper. REFERENCES: [1] AASHTO. Standard Specifications for Transportation Materials and Methods of Sampling and Testing.

Part I, Specifications; Part II, Tests. American Association of State Highways and Transportation Officials, Washington, D.C., 1978.

[2] Hogentogler, C.A. and K. Terzaghi. Interrelationship of Load, Road and Subgrade. Public Roads, Volume10, Number 3, 1929.

[3] ASTM D2487 Standard: Classification of Soils for Engineering Purposes (Unified Soil Classification System). American Society for Testing and Material, Annual Book of ASTM Standards, Volume 04.08, Soil and Rock, 1986.

[4] Nogami, J.S. and D.F. Villibor. Uma Nova Classificação para Finalidades Rodoviárias, Proceedings SIMP. BRAS. SOLOS TROPICAIS EM ENG., COPPE/ABMS, Rio de Janeiro, Brasil, Rio de Janeiro, 1981, pp.30-40.

[5] Nogami, J.S. and D.F. Villibor. Additional Considerations about a New Geotechnical Classification for Tropical Soils. Proceedings, First International Conference on Geomechanics in Tropical Lateritic and Saprolitic Soils, Brasília, Brasil, 1985, Volume 1, pp. 165-174.

[6] Parsons, A.W. The rapid measurement of the moisture condition of earthwork material. TRRL Report 750, Crowthorne, U.K., 1976.

[7] Parsons, A.W. and J.B. Borden. The moisture condition test and its potential applications in earthworks. TRRL Supplementary Report 522, Crowthorne, U.K., 1979.

[8] Nogami, J.S. and V.M.N. Cozzolino. A Identificação de Solos Tropicais: dificuldades e proposta de um método preliminar. Proceedings, Anais da 20ª Reunião Anual de Pavimentação, Fortaleza, Ceará, Brasil, 1985, Volume 2.

[9] Fortes, R.M. Método Expedito de Identificação MCT de Solos Tropicais, para Finalidades Rodoviárias, Utilizando-se Anéis de PVC Rígido. Dissertação de Mestrado, Escola Politécnica da Universidade de São Paulo, São Paulo, Brasil, 1990, 210p.

[10] Fortes, R.M. and Nogami, J.S. Método Expedito de identificação do grupo MCT de Solos Tropicais, utilizando-se anéis de PVC Rígido. Proceedings,Anais da 25ª Reunião Anual de Pavimentação, São Paulo, Brasil, 1991,Volume1, pp. 591-604.

[11] Nogami, J.S. and D.F. Villibor. A new simple method for classification of lateritic and saprolitic soils. Proceedings, 7th International IAEG Congress, Balkema, Rotterdam, Netherland, 1994, ISBN 90 5410503 B, pp. 3391-3399.

© Copyright IJP 2003 Volume 2 Number 3 September 2003 Page 13

[12] Nogami, J.S. and D.F. Villibor. Identificação Expedita dos Grupos de Classificação MCT para Solos Tropicais. Proceedings, Anais do 10° COBRAMSEF, Foz do Iguaçu, Paraná, Brasil, 1994, Volume 4, pp. 1293-1300.

[13] Nogami, J.S. and D.F. Villibor. Importância e determinação do Grau de Laterização em Geologia de Engenharia. Proceedings, Anais do VIII Congresso da ABGE, Rio de Janeiro , Brasil, 1996, Volume 1, pp. 345-358.

[14] Villibor, D.F., J.S. Nogami, M. Beligni, and J.R. Cincerre. Pavimentos com Solos Lateríticos e Gestão de Manutenção de Vias Urbanas. ABPv – Associação Brasileira de Pavimentação e Universidade Federal de Uberlândia, Faculdade de Engenharia Civil, São Paulo, Brasil, 2000.

[15] Fortes, R.M. Método das Pastilhas para Identificação Expedita do Grupo MCT – Miniatura, Compactada, Tropical. 1ª Câmara Permanente de Desenvolvimento Tecnológico, Universidade Mackenzie, São Paulo, SP, Brasil, 1997.

[16] Fortes, R.M., J.V. Merighi, and A. Zuppolini Neto. Método das Pastilhas para Identificação Expedita de Solos Tropicais. Proceedings, 2º Congresso Rodoviário Português, Lisboa, Portugal, 18 a 20 de novembro de 2002, LNEC, Volume II, pp. 17-28.

[17] Briganti, L. A. and J.V. Merighi. O projeto de restauração de pavimento do programa BID/DER: estudo de caso. 2º Simpósio sobre obras rodoviárias – RODO’2002, Brasil.

![[Tela 300 v1.0.0] Cargo: P03 - PERITO CRIMINAL - … · 08/05/2018 GABARITO DA PROVA OBJETIVA- …](https://static.fdocumentos.com/doc/165x107/5bf7e94d09d3f209398bd563/tela-300-v100-cargo-p03-perito-criminal-08052018-gabarito-da-prova.jpg)