Res Sim Glossary

-

Upload

nataly-guevara -

Category

Documents

-

view

239 -

download

1

Transcript of Res Sim Glossary

CONTENTS

1 GLOSSARY OF COMMON TERMS AND CONCEPTS IN RESERVOIR SIMULATION AND FLOW THROUGH POROUS MEDIA 1.1 Some General Defi nitions 1.2 Reservoir Fluid Properties 1.3 Single Phase Rock Properties 1.4 Multi-Phase Rock/Fluid Properties 1.5 Wettability and Fluid Displacement Processes 1.6 Oil Recovery Methods, Waterfl ood Patterns and Sweep Effi ciency 1.7 Terms Used in Numerical Reservoir Simulation 1.8 Numerical Solution of the Flow Equations in Reservoir Simulation 1.9 Pseudo-Isation and Upscaling 1.10 Numerical Simulation of Flow in Fractured Systems 1.11 Miscellaneous - Vertical Equilibrium, Miscible Displacement and Dispersion

Glossary of Terms

2

Glossary of Terms

3Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

1 GLOSSARY OF COMMON TERMS AND CONCEPTS IN RESERVOIR SIMULATION AND FLOW THROUGH POROUS MEDIA

This glossary is intended for use by the reader as a quick reference to terms used commonly in reservoir engineering in general and in reservoir simulation in particular. The student is not expected to work through this from begining to end in a systematic manner. However, the students should make sure that he or she is quite familiar with all the technical terms that appear in the main text of this unit. It is hoped that this is of particular use for distance learning students who may have studied the reservoir engineering distance leasrning unit some time ago but hopefully it will also be of use to our residential students.

1.1 Some General Defi nitionsOilfi eld Units volumes in oilfi eld units are barrels (bbl or B); 1 bbl = 5.615 ft3 or 0.159 m3. A stock tank barrel (STB) is the same volume defi ned at some surface standard conditions (in the stock tank) which are usually 60oF and 14.7 psi. A reservoir barrel (RB) is the same volume defi ned at reservoir conditions which can range from ~ 90oF and 1500 psi for shallow reservoirs to > 350oF and 15,000 psi for very deep (high temperature - high pressure, HTHP) reservoirs. Note that when 1RB of oil is produced it gives a volume generally less than 1B at the surface since it loses its gas. (See formation volume factor.)

Oil Types: Dry gas; Wet gas; Gas Condensate; Volatile oil; “Black” oil; Heavy (viscous) oil; Tar - see Tables 1 and 2 below.

DDew PPooiint

BubblePoiinntt

LLiqquidVooVoV

llume

Paat

hof

Pro

dduct

ion

Bubble PointBubble Pointor

Dissolved GasDissolved GasReservoirsReservoirs

0 50 100 150 200

Reservoir Temperature, Temperature, T ºF

Res

ervo

ir P

ress

ure,

PS

IA

250 300 350

Dew PointDew Pointor

RetrogradeRetrogradeGas-CondensateGas-Condensate

ReservoirsReservoirs

B1

C

C1

B

B2

D

B3A2

AA

AA1

Single PhaseSingle PhaseGas ReservoirsGas Reservoirs

4000

3500

3000

2500

2000

1500

1000

500

Pat

h of

Res

ervo

ir F

lui

Pat

h of

Res

ervo

ir F

luid

Cric

onde

nthe

rm =

250

C

ricon

dent

herm

= 2

50 º

F

TTc =

127

ºFF

CriticalCriticalPointPoint

80%

40%

20%

10%

5%

0%Figure 1Pressure Temperature Phase Diagram of a Reservoir Fluid

4

Glossary of Terms

Reservoir Surface GOR API Typical Composition, Mole % Fluid Appearance Range Gravity

C1 C2 C3 C4 C5 C6+

Dry gas Colourless gas Almost no liquids - 100

Wet gas Colourless gas - >100 Mscf/bbl 60o -70o 96 2.7 0.3 0.5 0.1 0.4 some clear or straw-coloured liquid

Condensate Colourless gas - 3-100 50o-70o 87 4.4 2.3 1.7 0.8 3.8 significant amounts Mscf/bbl of light coloured (900-18000 m3/m3) liquid

“Volatile” or Brown liquid - "3000 40o-50o 64 7.5 4.7 4.1 3.0 16.7high shrinkage various yellow, red, scf/bbl oil or green hues (500 m3/m3)

“Black” or Dark brown 100- 2500 30o-40o 49 2.8 1.9 1.6 1.2 43.5 low shrinkage to black viscous scf/bbl oil liquid (20 - 450 m3/m3)

Heavy oil Black viscous liquid Almost no gas 10o-25o 20 3.0 2.0 2.0 12.0 71 in solution

Tar Black substance No gas < 10o - - - - - 90+ viscosity > 10,000cp

Component Black Oil Volatile Oil Gas-Condensate Dry Gas Gas

C1 48.83 64.36 87.07 95.85 86.67 C2 2.75 7.52 4.39 2.67 7.77 C3 1.93 4.74 2.29 0.34 2.95 C4 1.60 4.12 1.74 0.52 1.73 C5 1.15 2.97 0.83 0.08 0.88 C6 1.59 1.38 0.60 0.12 .... C7

+ 42.15 14.91 3.80 0.42 ....

Mol. Wt. C7+ 100.00 100.00 100.00 100.00 100.00 GOR, SCF/bbl 225 181.00 112 157 .... Tank gravity, 625 2000 18,200 105,000 Inf. 0API Liquid 34.3 50.1 60.8 54.7 .... color Greenish Medium Light Water Black Orange Straw White

1.2 Reservoir Fluid PropertiesPhase: A chemically homogeneous region of fl uid which is separated from another phase by an interface e.g. oleic (oil) phase, aqueous phase (mainly water), gas phase, solid phase (rock). There is no particular symbol but frequently subscripted o, w, g; phases are immiscible.

Table 1Describing various oil types from dry gas to tar

Table 2Mole Composition and Other Properties of Typical Single-Phase Reservoir Fluids

5Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Inter Facial Tension (IFT): The IFT between two phases is a measure of energy required to create a certain area of the interface. Indeed, the IFT is given in dimensions which are energy per unit area. The symbol for IFT is σ and units are dyne/cm in σ and units are dyne/cm in σc.g.s. units and N/m (newtons per m) in S.I. units. For example, if both gas and oil are present in a reservoir then the gas/oil IFT may be in the range, σgo ~ 0.1-10 mN/m; likewise. The oil/water value may be in the range, σ0w ~ 15 - 40 mN/m. Note that numerically 1mN/m = 1dyne/cm.

Component: A single chemical species that may be present in a phase; e.g. in the aqueous phase there are many components - water (H2O), sodium chloride (NaCl), dissolved oxygen (O2) etc.; in the oil phase there can be hundreds or even thousands of components - hydrocarbons based on C1, C2, C3, etc. Some of these oil components are shown in Table 2.

Viscosity: The viscosity of a fl uid is a measure of the (frictional) energy dissipated when it is in motion resisting an applied shearing force; dimensions [force/area.time] and units are Pa.s (SI) or poise (metric). The most common unit in oilfi eld applications is centiPoise (cP or cp). Typical example are:- water viscosity at standard conditions, μw ~ 1 cP; typical light North Sea oils have μo ~ 0.3 - 0.6 cP at reservoir conditions (T ~ 200oF ; P ~ 4000 - 6000 psi); at reservoir conditions, medium viscosity oils have μo ~ 1 - 6 cP; moderately viscous oils have μo ~ 6 - 50 cP; very viscous oils may have μo ~ 50 - 1000s cP and tars may have μo ~ up to 10000 cP.

Formation Volume Factor: The factor describing the ratio of volume of a phase (e.g. oil, water) in the “formation” (i.e. reservoir at high temperature and pressure) to that at the surface; symbols Bw, Bo etc. For oil, a typical range for Bo is ~1.1 - 1.3 since, at reservoir conditions, it often contains large amounts of dissolved gas which is released at surface as the pressure drops and the oil shrinks; oilfi eld units [reservoir barrels/stock tank barrel (RB/STB)].

API Gravity (°API): Defi nition =

Gas Solubility Factors (or Solution Gas/Oil Ratios): These factors describe the volume of gas (usually in standard cubic feet, SCF) per volume of oil (usually stock tank barrel, STB); symbol, Rso and Rsw; units SCF/STB.

Compressibility: The compressibility (c) of a fl uid (oil, gas, water) or rock formation can be defi ned in terms of the volume (V) change or density (ρ) change with pressure as follows:

c

VVP P

= − ∂∂

P PP PP PP P

P PP P = ∂

∂P P∂P PP PP PP PP P

P PP P

1 1V1 1V∂1 1∂1 1

1 1 1 11 1

ρP PρP Pρ

Note that this quantity is normally expressed in units of psi-1.

Typical ranges of compressibilities are presented below (from Craft & Hawkins (Terry revision), 1991):

6

Glossary of Terms

Compressibilities (units of 10-6 psi-1)

Formation rock 3 - 10 Water 2 - 4 Undersaturated Oil 5 - 100 Gas at 1000psi 900 - 1300 Gas at 5000psi 50 - 200

Compressibilities are used in reservoir engineering for Material Balance Calculations.

Material Balance Equations: Material Balance applied to a reservoir is simply a volumetric balance. It may be expressed as an equation which relates: • The quantities of oil, gas and water produced.

• The reservoir (average) pressure.

• The quantity of water infl ux (e.g. from the aquifer).

• The initial oil and gas content of the reservoir.

Essentially the material balance equations described how the energy of expansion and infl ux “drive” production in the reservoir. If there is a suffi ciently low (or zero) fl uid infl ux, the reservoir pressure will decline. One form of the Material Balance Equation is given below where each term on the left-hand side described a mechanism of fl uid production (from Craft & Hawkins (Terry revision), 1991):

N B BN m B

BB B m N B

c S c

Sp Wp W

N B B B W

t tN Bt tN B itiBtiB

giBgiB g gB Bg gB B i tm Ni tm N Bi tBiw wc Sw wc S i f

wiSwiS ep Wep W

p tN Bp tN B g wB Bg wB B pWpW

.(N B.(N B ). .N m. .N m

.( ) (i t) (i t).m N).m Ni t).i tm Ni tm N).m Ni tm N. .i t. .i tBi tB. .Bi tBi. .ic S.c Sc Sw wc S.c Sw wc S

.

. (N B. (N Bp t. (p tN Bp tN B. (N Bp tN B .

− +B− +Bt t− +t tBt tB− +Bt tBi− +i )− +) − +B B− +B Bg g− +g gB Bg gB B− +B Bg gB B i t− +i t) (− +) (i t) (i t− +i t) (i t+i t+i t

+−

p W+p W

= +N B= +N BN Bp tN B= +N Bp tN BN B. (N B= +N B. (N BN Bp tN B. (N Bp tN B= +N Bp tN B. (N Bp tN B[ ]R R[ ]R R B B[ ]B Bp t[ ]p t p[ ]pR RpR R[ ]R RpR Rsoi[ ]soiR RsoiR R[ ]R RsoiR R g w[ ]g wB Bg wB B[ ]B Bg wB B. ([ ]. (N B. (N B[ ]N B. (N Bp t. (p t[ ]p t. (p tN Bp tN B. (N Bp tN B[ ]N Bp tN B. (N Bp tN B ).[ ]).. (= +. ([ ]. (= +. (N B. (N B= +N B. (N B[ ]N B. (N B= +N B. (N Bp t. (p t= +p t. (p t[ ]p t. (p t= +p t. (p tN Bp tN B. (N Bp tN B= +N Bp tN B. (N Bp tN B[ ]N Bp tN B. (N Bp tN B= +N Bp tN B. (N Bp tN B R R−R R[ ]R R−R R B B+B BB Bg wB B+B Bg wB B

1i t1i t 1∆p W∆p W

Where the terms have the following meaning: N = initial reservoir oil, STB; Np = cumulative produced oil, STB Boi = initial oil formation volume factor, bbl/STB Bo = oil formation volume factor, bbl/STB Bgi = initial gas formation volume factor, bbl/STB Bg = gas formation volume factor, bbl/STB Bw = water formation volume factor, bbl/STB Rsoi = initial solution gas-oil ratio, SCF/STB Rp = cumulative produced gas-oil ratio, SCF/STB Rso = solution gas-oil ratio, SCF/STB We = water infl ux into the reservoir, bbl Wp = cumulative produced water, bbl cw = water isothermal compressibility, psi-1 cf = formation isothermal compressibility, psi-

∆ p = change in average reservoir pressure, psi

7Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Swi = initial water saturation m = (Initial hydrocarbon vol. of gas cap)/(Initial hydrocarbon vol. of oil)

In practice the material balance equation is often applied in the “linear form” of Havlena and Odeh (J. Pet. Tech., pp896-900, Aug. 1963; ibid, pp815-822, July 1964); see discussion in Craft & Hawkins (Terry revision, 1991).

In the above formulation of the Material Balance Equation, the various terms have the following interpretation.

Left-Hand Side of the Material Balance Equation

• The following terms account for the expansion of any oil and/or gas zones that may be present in the reservoir:

N B BN m B

BB Bt ti

ti

gig gB Bg gB B i.(N B.(N B )

. .N m. .N m.( )− +B− +Bt t− +t tBt tB− +Bt tB i− +i )− +) B B−B B

• The following term accounts for the change in void space volume which is the expansion of the formation and the connate water:

( ). . . .( )1( )

1( )+( )

+−

m N( )m N( ). .m N. . Bc S.c S. c

SptiBtiB w wc Sw wc S.c S.w w.c S. i f

wiSwiS∆p∆p

• The next term is the amount of water influx that has occurred into the reservoir:

We

Right-Hand Side of the Material Balance Equation

• The fi rst term of the RHS represents the production of oil and gas:

= +[ ]N B= +N B= +[ ]R R[ ]−[ ]−R R−[ ]−[ ]B[ ]p t[ ]p t[ ]N Bp tN B= +N B= +p t= +N B= +[ ]p[ ][ ]R R[ ]p[ ]R R[ ][ ]soi[ ][ ]R R[ ]soi[ ]R R[ ][ ]g[ ][ ]B[ ]g[ ]B[ ]. ([ ]. ([ ]= +[ ]= +. (= +[ ]= +N B. (N B= +N B= +. (= +N B= +[ ]N B[ ]. ([ ]N B[ ]= +[ ]= +N B= +[ ]= +. (= +[ ]= +N B= +[ ]= +p t. (p t[ ]p t[ ]. ([ ]p t[ ]= +[ ]= +p t= +[ ]= +. (= +[ ]= +p t= +[ ]= +N Bp tN B. (N Bp tN B= +N B= +p t= +N B= +. (= +N B= +p t= +N B= +[ ]N B[ ]p t[ ]N B[ ]. ([ ]N B[ ]p t[ ]N B[ ]= +[ ]= +N B= +[ ]= +p t= +[ ]= +N B= +[ ]= +. (= +[ ]= +N B= +[ ]= +p t= +[ ]= +N B= +[ ]= +[ ]).[ ]

• The second term of the RHS represents the production of water:

Bw.Wp

1.3 Single Phase Rock PropertiesPorosity: the fraction of a rock that is pore space; common symbol, φ Porosity varies from φ ≈ 0.25 for a fairly permeable rock down to φ ≈ 0.1 for a very low permeability rock; there may be an approximate correlation between k and φ.

Pores & pore throats: The tiny connected passages that exist in permeable rocks; typically of size 1μm to 200 μm; they are easily visible in s.e.m. (scanning electron microscopy). Pores may be lined by diagenetic minerals e.g. clays. The narrower constrictions between pore bodies are referred to as Pore Throats. See Figure 2:

8

Glossary of Terms

~1mm

quartz

illite

10mm

illite

quartz

Permeability: The fl uid (or gas) conducting capacity of a rock is known as the permeability; symbol k ; units Darcy (D) or milliDarcy (mD); dimensions -> [L]2. Permeability is found experimentally using Darcy's Law (see below). Permeability can be anisotropic and show tensor properties (see below) - denoted tensor properties (see below) - denoted tensor k . Probably the most important quantity from the point of view of the reservoir engineer since its distribution dictates connectivity and fl uid fl ow in a reservoir. Timmerman (p. 83, Vol. 1, Practical Reservoir Engineering, 1982) presents the rule:

Classifi cation Permeability Range (mD) poor to fair 1 - 15 moderate 15 - 50 good 50 - 250 very good 250 - 1000 excellent > 1000

k/φ Correlations: It has been found in many systems that there is a relationship between permeability, k, and porosity, φ. This is not always the case and much scatter can be seen in a k/φ crossplot. Broadly, higher permeability rocks have a higher porosity and some of the relationships reported in the literature are shown below. Some examples of k/φ correlations which have appeared in the literature are shown in Figure 3:

Figure 2

9Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

100.0

10,000

1,000

100

10

1

50.0

10.0

5.0

1.0

0.5

0.1

0.05

0.01

6

0 10 20 30

8 10 12 14 16 18 20 22Core Porosity (%)

Core Porosity (%)

Cor

e P

erm

eabi

lty (

md)

Cor

e P

erm

eabi

lty (

md)

100.0

10,000

1,000

100

10

1

50.0

10.0

5.0

1.0

0.5

0.1

0.05

0.01

6

0 10 20 30

8 10 12 14 16 18 20 22Core Porosity (%)

Core Porosity (%)

Cor

e P

erm

eabi

lty (

md)

Cor

e P

erm

eabi

lty (

md)

Darcy’s Law: Originally a law for single phase fl ow that relates the total volumetric fl ow rate (Q) of a fl uid through a porous medium to the pressure gradient (∂P/∂x) and the properties of the fl uid (μ = viscosity) and the porous medium (k = permeability; A = cross-sectional area): Note that Darcy's law can be used to defi ne permeability using the quantities defi ned in Figure 5 as follows:

Figure 3Permeability/Porosity Correlation for Cores from the Bradford Sandstone

Figure 4Permeability/Porosity Correlation for Cores from the Brent Field

10

Glossary of Terms

Q

k A Px

= −

∂∂

.k A.k A

µ

Note that the β in the equation in Figure 5 is a factor for units conversion (see Chapter 2).

Darcy Velocity: This is the velocity, u, calculated as, u = Q/A; this may be expressed as,

uQA

k Px

= == = −

k Pk P

k Pk P

k Pk P

∂k P∂k P∂

k Pk P

k Pk P

k Pk P

µ

Pore Velocity: This is the fl uid velocity, v, given by,

v = == =Q

Au

.φ φ

∆P

L

Q = β.k.A

µ.

∆P∆P∆L

Permeability Anisotropy: Since permeability can be directional, then it is possible for kx ≠ ky ≠ kz in a given system. This is often seen in practice when comparing the horizontal permeability, (kh), with the vertical permeability, (kv) - usually as the ratio, (kv/kh). It is often found (kv/kh) < 1, i.e. there is more resistance to vertical fl ow than horizontal fl ow. The value of (kv/kh) must be evaluated with respect to the scale (i.e. the size) of the sample or system. The value of this quantity will be different in a core plug or in a large simulator grid block in which the core plug was a small part. The origin of the anisotropy may be quite different in each case.

At the small (core plug) scale, anisotropy may come from fabric anisotropy at the grain level or from lamination at the slightly larger scale (laminaset scale). At the larger scale (grid block), the anisotropy may arise from larger scale heterogeneity, even though locally the component rock facies are completely isotropic. This is illustrated in Figure 6.

Figure 5Schematic of the Single Phase Darcy Law

11Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Fabric Anistropy

Heterogeneity Anistropy

Lamination

Small Scale

Grid Block Scale (100s m)

Core Plug

Rock GrainsHi k lamina

Lo k lamina

For Whole System

Low Perm Lensesor Shales

kh

kv

kv

(kv/kh) = 1

Low Perm Sand(kv/kh) = 1

kh

1.4 Multi-Phase Rock/Fluid PropertiesSaturation: The saturation of a phase (oil, water, gas) is the fraction of the pore space that it occupies (not of the total rock + pore space volume); symbols Sw, Soand Sg ; saturation is a fraction, where Sw + So + Sg = 1. Multi-phase fl ow functions such as relative permeability and capillary pressure (see below) depend strongly on the local fl uid saturations.

Residual Saturation: The residual saturation of a phase is the amount of that phase (fraction pore space) that is trapped or is trapped or is trapped irreducible; e.g. after many pore volumes of water displace oil from a rock, we reach residual oil saturation, Sor; the corresponding connate (irreducible) water level is Swc (or Swi); the related trapped gas saturation is Srg; at the residual or trapped phase saturation the corresponding relative permeability(see below) of that phase is zero. Strictly, we should refer to the phases in terms of wetting and non-wetting phases - the residual phase of non-wetting phase is trapped in the pores by capillary forces. Typically, in a moderately water wet sandstone, Sor~ 0.2 - 0.35. The amount of trapped or residual phase depends on the permeability and wettability of the rock and a large amount of industry data is available on this quantity: For example, the relationship for k vs. Swc (or Swi) is shown for a range of reservoir formations, Figure 7.

Figure 6Permeability anistropy at different scales

12

Glossary of Terms

1

3 2

12

1310

117

9

8

645

11A

10,000

5,000

1,000

500

100

50

10

5

1.0

1 = Hawkins2 = Magnolia3 = Washington4 = Elk Basin5 = Tangely6 = Creole7 = Synthetic Alundum8 = Lake St John

0 10 20 30 40 50 60 70 80 90 100

% Connate water

Air

Per

mea

bilit

y (m

D)

9 = Louisiana Gulf Coast Miocene Age-Well A10 = Ditto-Wells Band C11 = North Belridge California11A = North Belridge California Core Analysis Data12 = Dominguez Second Zone13 = Ohio Sandstone

Relative Permeability: A quantity (fraction) that describes the amount of impairment to fl ow of one phase on another. It is defi ned in the two phase Darcy law (see notes); depends on the Saturation of the phase; e.g. in two phase fl ow -> krw and kro depend on Sw (since Sw + So = 1).

A schematic of the Two Phase Darcy Law showing the defi nition of Relative Permeability is presented in Figure 8.

At steady-state fl ow conditions, the oil and water fl ow rates in and out, Qo and Qw, are the same:

Figure 7Correlation between (air) permeability and the connate water (Swc) for a wc) for a wc

range of reservoir rocks

13Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Qw

Qo

Qw

∆Po

∆Pw

LQo

At steady-state flow conditions, the oil and water flow rates in and out, Qo and Qw are the same

NB the Units for the two-phase Darcy Law are exactly the same as those in Figure 2

The two-phase Darcy Law is as follows:

kro

krw

Sw

1

00 1

Scematic of relative permeability,krw and kro

Rel.Perm.

Qw and Qo = volumetric flow rates of water and oilA = cross-sectional areaL = system lengthµw and µo = system lengthk = absolute permeabilities∆Pw and ∆Po = the pressure drops across the water and oil phases at steady-state flow conditionskrw and kro = the water and oil relative permeabilities

Where:

Qk k A P

L

Qk k A P

L

wrw

w

w

oro

o

o

=

=

. . .

. . .

µ

µ

∆

∆

The two-phase Darcy Law is as follows:

Where: Qw and Qo = Volumetric fl ow rates of water and oil; A = Cross-sectional area; L = System length; μw and μo = Water and oil viscosities; k = Absolute permeabilities; ΔPw and ΔPo = The pressure drops across the water and oil phases at steady-state fl ow conditions krw and kro = The water and oil relative permeabilities

Several further examples of relative permeabilities and capillary pressure are given later in this glossary. Note that the Units for the two-phase Darcy Law are given in Figure 2, Chapter 2.

Capillary Pressure: The difference in pressure between two (immiscible) phases; defi ned as the non wetting phase pressure minus the wetting phase pressure; depends on the saturation - for two phases capillary pressure, Pc(Sw) = Po- Pw (for a water wet porous medium). The following fi gures show schematic fi gures for Capillary Pressure (Pc(Sw)) and Relative Permeability (krw(Sw) and kro(Sw)) for a water wet system:

Figure 8The two-phase Darcy Law and relative permeability

14

Glossary of Terms

Swc

Pc

Sw

krel

Sor

Capillary Pressure

Swc

kro

krw

Sw

Sor

Relative Permeability

Mobility and Mobility Ratio: the mobility of a phase (e.g. λw or λo) is defi ned as the effective permeability of that phase (e.g. kw = k . krw ; ko = k . kro) divided by the viscosity of that phase;

λ

µλ

µwrw

wo

ro

o

k k k k=

=

.k k.k k;

.k k.k k

Mobility ratio, M, is given by:

M

kk

o

w

ro w

rw o

= == =o= =o

λλ

µµ

..

Fractional Flow: The Fractional Flow of a phase is the volumetric fl ow rate of the phase under a given pressure gradient, in the presence of another phase. The symbols for water and oil fractional fl ow are fwsymbols for water and oil fractional fl ow are fwsymbols for water and oil fractional fl ow are f and fo and they depend on the phase saturation, Sw:

f

fQQ

Q Q Qwfwfw

To

o

TT oQ QT oQ Q w= == =w= =w = +Q Q= +Q QT o= +T oQ QT oQ Q= +Q QT oQ Q; ;; ;f; ;f

Q; ;

; ;Qo; ;ofof; ;fof

o; ;o= =; ;= =f= =f; ;f= =f; ; ; ;where

The fractional fl ows play a central part in Buckley-Leverett (B-L) theory of linear displacement which starts from the conservation equation:

∂∂

= − ∂

∂

∂

∂

= − ∂

∂

S

tfx

St

fx

w ww ww w = −w w= − ∂w w∂w ww wfw wf o o∂o o∂o oo oo oo o = −o o= −o o

fo of;

Buckley-Leverett Theory: This mathematical theory of viscous dominated water → oil displacement is based on the fact that the velocity, vSw, of a fi xed saturation value Sw is given by:

v vSwv vSwv v w

w

fwfw

Sv v=v v

∂∂

.

Figure 9Schematics of capillary pressure and relative permeability for a water-wet system

15Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

where v is the fl uid velocity, v = Q/(Aφ) and (dfw) and (dfw) and (df /dSw) is the slope of the fractional fl ow curve. The relationship between the fractional fl ow and Buckley Leverett theory is illustrated in Figure 10.

Sor

Swc Swf

Sw Swf

Sor

Swc

FractionalFlow

of Water,

Water Saturation, Sw

Flood FrontHeight

Length, (x/L)

Fractional Flow Welge Tangent

fw

"Buckley-Leverett" Saturation Profile

1.5 Wettability and Fluid Displacement ProcessesWettability: This is a measure of the preference of the rock surface to be wetted by a particular phase - aqueous or oleic - or some mixed or intermediate combination. The Wettability of a porous medium determines the form of the relative permeabilities and capillary pressure curves; a very complex subject which is still the subject of much research. We refer to: Water wet, Oil wet and Intermediate wet systems in the following defi nitions.

Water-Wet: Water-wet formation: Where water is the preferential wetting phase. Water occupies the smaller pores and forms a fi lm over all of the rock surface - even in the pores containing oil. A Waterfl ood in such a system would be an imbibitionprocess (see below). Water would spontaneously imbibe (see below) into a water-wet core containing mobile oil at Sor, hence displacing the oil.

Oil-Wet: Oil-wet formation: Where oil is the preferential wetting phase. Oil occupies the smaller pores and forms a fi lm over all of the rock surface - even in the pores containing water. A Waterfl ood in such a system would be a drainage process (see below). Oil would spontaneously imbibe into an oil-wet core containing mobile water at Swr, displacing the water.

Intermediate-Wet: An Intermediate wet formation is where some degree of water wetness and oil wetness is shown by the same rock. Some different types of intermediately wet system have been identifi ed known as Mixed wet and Mixed wet and Mixed wet Fractionally wet. Both water and oil may spontaneously imbibe (see below) into such a system to some degree and indeed this forms the basis for certain Wettability Tests known as the Amott Test and the Amott Test and the Amott USBM Test (USBM => United States Bureau of Mines). USBM Test (USBM => United States Bureau of Mines). USBM Test

Drainage: A Drainage displacement process is when the non-wetting phase is increasing. For example, in a water wet porous medium, drainage would be oil displacing water. The drainage and imbibition capillary pressure curves and relative permeabilities are different since these petrophysical functions depend on the saturation history. A simple schematic of a drainage process is shown in Figure 11.

Figure 10Relationship between the fractional fl ow function and the Buckley-Leverett front height

16

Glossary of Terms

Qo

Qw

Oil Injection Water Wet Coreat 100% Water

Water Injection

Water imbibes intocore displacingoil-water wet orintermediate wetsystem

Water Wet Coreat sor

Core at swc

Oil

Water

Imbibition: An Imbibition displacement process is when the wetting phase is increasing. For example, in a water wet porous medium, drainage would be water displacing oil as shown in Figure 12. The drainage and imbibition capillary pressure curves and relative permeabilities are different since these petrophysical functions depend on the saturation history.

Qo

Qw

Oil Injection Water Wet Coreat 100% Water

Water Injection

Water imbibes intocore displacingoil-water wet orintermediate wetsystem

Water Wet Coreat sor

Core at swc

Oil

Water

Spontaneous Imbibition: This process occurs when a wetting phase invades a porous medium in the absence of any external driving force. The wetting fl uid is “sucked in” under the infl uence of the surface forces. For example, if we have a water wet core at irreducible water saturation, Swr, then water may spontaneously imbibe and displace the oil as shown in Figure 13.

The observed behaviour in a system of Intermediate Wettability is shown in Figure 14 where we see that both phases can spontaneously imbibe under certain conditions.

Qo

Qw

Oil Injection Water Wet Coreat 100% Water

Water Injection

Water imbibes intocore displacingoil-water wet orintermediate wetsystem

Water Wet Coreat sor

Core at swc

Oil

Water

Core at swc Core at sorOil

Water

Pc

Swc

kro

krw

Sor

d

di

i

Sw

Drainage

Drainage and ImbibitionCapillary Pressure

Drainage (d) and Imbibition (i)Relative Permeabilities

Imbibition

Sw

krel

Primary and Secondary Recovery Processes: Primary and Secondary processes refer to the stage in the fl uid displacement when one phase displaces another. For example, in a water wet porous medium (--> means displaces) :

Figure 14Intermediate wettability.Both water and oil may spontaneously imbibe into the core displacing the other phase. Shows both water wet and oil wet character

Figure 11Drainage

Figure 12Imbibtion

Figure 13Spontaneous Imbibition

17Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Primary drainage: is oil --> water from a core at 100% water saturation to Swr. Secondary imbibition: is water --> oil from a core at Swr and mobile oil to Sor.

Examples: Figures 15 and 16 show schematics of typical Drainage and Imbibition capillary pressure (Pc) and relative permeability (krw and kro) curves for a water wet system. Primary Drainage (oil --> water from core at 100% water) and Secondary Imbibition (water --> oil from core at Swr) processes are illustrated:

Pc

Swc

kroro

krw

Sor

d

di

i

Sw

Drainage

Drainage and ImbibitionCapillary Pressure

Drainage (d) and Imbibition (i)Relative Permeabilities

Imbibition

Sw

krel

DrainageDrainage

ImbibitionImbibition

100

100

80

80

60

60

40

40

20

200

0Wetting Phase Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

%

Examples: Further examples of experimental capillary pressures and relative permeabilities in cores are shown for various processes (Drainage and Imbibition) and wettability conditions (Water wet and Intermediate wet) in fi gure 17,18,19 and 20 on the following pages.

Figure 15Drainage and imbibition capillary pressures

Figure 16Drainage and imbibition relative permeability char-acteristics

18

Glossary of Terms

liO

retaW

100

100

80

80

60

60

40

40

20

200

0Water Saturation, %PV

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

nR

elat

ive

Per

mea

bilit

y, F

ract

ion

liO

retaW

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

liO

retaW

100

100

80

80

60

60

40

40

20

200

0Water Saturation, %PV

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

nR

elat

ive

Per

mea

bilit

y, F

ract

ion

liO

retaW

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

100

100

80

80

60

60

40

40

20

200

0Water Saturation, %PV

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

nR

elat

ive

Per

mea

bilit

y, F

ract

ion

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

retaW

liO

retaW

li

O

Figure 17Typical water-oil relative permeability characteristics, strongly water-wet rock

Figure 18Typical water-oil relative permeability characteristics, strongly water-wet rock

Figure 19Typical water-oil relative permeability characteristics, strongly oil-wet rock

19Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

n

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

rretaW

li

O

Examples: Experimental Capillary Pressures in cores for various processes (Drainage and Imbibition) and wettability conditions (Water wet, Oil Wet and Intermediate Wet). Figure 21.

Figure 20Typical water-oil relative permeability characteristics, strongly oil-wet rock

20

Glossary of Terms

Water Wet48

40

32

24

16

8

0

20

16

12

8

4

0

0 20 40 60 80 100

12

Water Saturation - %

0 20 40 60 80 100Water Saturation - %

0 20 40 60 80 100Water Saturation - %

Cap

illar

y P

ress

ure

- C

m o

f Hg

Cap

illar

y P

ress

ure

- C

m o

f Hg

Oil Wet

Intermediate Wet

48

40

32

24

16

8

00 20 40 60 80 100

Oil Saturation - %

Cap

illar

y P

ress

ure

- C

m o

f Hg

32

24

-24

16

-16

8

-8

0

Cap

illar

y P

ress

ure

- C

m o

f Hg

Venango core VL-2k = 28.2 md

1

2

1

2

3

Capillary Pressure Characteristics,Strongly Water-Wet Rock.

Curve 1 - DrainageCurve 2 - Imbibition

Capillary Pressure Characteristics,(After Ref. 30)

Oil-Water Capillary Pressure Characteristics,Ten-Sleep Sandstone, Oil-Wet Rock

(After Ref. 29).Curve 1 - DrainageCurve 2 - Imbibition

Oil-Water Capillary Pressure Characteristics,Intermediate Wettability.

Curve 1 - DrainageCurve 2 - Spontaneous Imbibition

Curve 3 Forced Imbibition

Figure 21

21Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Examples: Relative PermeabilititesExamples of experimental relative permeabilities in cores for Water Wet and Water Wet and Water Wet Oil Wet systems. Figure 22.Wet systems. Figure 22.Wet

100

100

80

80

60

60

40

40

20

200

0Water Saturation, %PV

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

nR

elat

ive

Per

mea

bilit

y, F

ract

ion

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

retaW

liO

retaW

li

O

liO

retaW

100

100

80

80

60

60

40

40

20

200

0Water Saturation, %PV

Water Saturation, %PV

Rel

ativ

e P

erm

eabi

lity,

Fra

ctio

nR

elat

ive

Per

mea

bilit

y, F

ract

ion

liO

retaW

1.0

0.1

0.01

0.001

0.00010 20 40 60 80 100

Typical Water-Oil Relative PermeabilityCharacteristics,

Strongly Water-Wet Rock

Typical Water-Oil Relative PermeabilityCharacteristics,

Strongly Oil-Wet Rock

Typical Water-Oil Relative PermeabilityCharacteristics,

Strongly Water-Wet Rock

Typical Water-Oil Relative PermeabilityCharacteristics,

Strongly Oil-Wet RockFigure 22

22

Glossary of Terms

EXAMPLES: Relative PermeabilititesA simple table summarising the typical characteristics of water-wet and oil-wet relative permeabilities is given below.

WATER WET OIL WET

Swc mostly > 20% < 15% (Often < 10%)

Sw wherekrw = kro Sw > 50% Sw < 50%(Points A on Figure 23)

krw at Sro krw < 0.3 krw > 0.5 (approaching 1)(Points B on Figure 23)

This is shown schematically in Figure 23:

retaW

liO

retaW

liO

100

100

60

60

40

40

80

80

20

200

0

100

100

60

60

40

40

80

80

20

200

0

A

A B

B

SwiSwi

Water-WetReservoir

Oil-WetReservoir

Water Saturation, %

Rel

ativ

e P

erm

eabi

lity,

% o

f Air

Per

mea

bilit

y

Water Saturation, %

In Water-Wet System

Sw mostly > 20%

At Point A: kro = krw ; Sw > 50%

krw at Sor / kro at Swi < 30%

In Oil-Wet System

Sw < 15%

At Point A: kro = krw ; Sw < 50%

krw at Sor / kro at Swi > 50%

1.6 Oil Recovery Methods, Waterfl ood Patterns and Sweep Effi ciencyHere we refer to the method used to develop the reservoir as follows:

• Primary Depletion - allowing the reservoir to produce under the original reservoir energy i.e. by natural expansion. If the pressure falls below the bubble point (Pb), then gas appears and the primary depletion process is known as solution gas drive:

• Secondary Recovery - where reservoir pressure is supported by injection, usually of water in waterfl ooding but early gas injection may be considered also as waterfl ooding but early gas injection may be considered also as waterfl oodingsecondary recovery In addition to supporting the pressure (maintaining reservoir energy), water or gas injection also displaces oil directly:

Figure 23Infl uence of wettability on relative permeability (after Fertl, OGJ, 22 May 1978)

23Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

• Tertiary Recovery or Enhanced Oil Recovery (EOR) or Improved Oil Recovery (IOR) - this refers to a range of methods which are designed to recover additional oil that would not be recovered by either Primary or Secondary Recovery.

Such methods include:

Thermal Methods - steam, in-situ combustion,.. Gas Injection - N2, CO2, hydrocarbon gas injection (usually after a waterfl ood) Chemical Methods - surfactant, polymer, alkali,.. Microbial Methods - using bugs to recover oil!

Waterfl ood Pattern: On-land Waterfl ooding is often carried out with the producers and injectors in a particular pattern. This is known as pattern fl ooding and examples of such patterns are: Five Spot, Nine Spot, Line Drive etc. as shown schematically in Figure 24.

Injection WellProduction WellPattern Boundary

Regular Four-Spot Skewed Four-Spot Normal Nine-Spot

Direct Line Drive Staggered Line Drive

Inverted Nine-Spot

Inverted Seven-SpotSeven-SpotFive-Spot

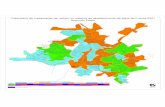

Areal Sweep Effi ciency: The Areal Sweep Effi ciency refers to the fraction of areal reservoir that is swept at a given pore volume throughput of displacing fl uid as shown schematically in Figure 25. For example, the Areal Sweep Effi ciency at Breakthrough for various processes (Waterfl ooding, Gas Displacement and Miscible fl ooding) is shown as a function of mobility ratio in Figure 26:

Figure 24Examples of areal patterns of injectors and producers (pattern fl ooding)

24

Glossary of Terms

High Areal Sweep Poor Areal Sweep

100

90

80

70

60

500.1 1.0 10.0

Mobility Ratio

Bre

akth

roug

h A

real

Sw

eep

Effi

cien

cy, %

Water→OilGas→OilMiscible

High Areal Sweep Poor Areal Sweep

100

90

80

70

60

500.1 1.0 10.0

Mobility Ratio

Bre

akth

roug

h A

real

Sw

eep

Effi

cien

cy, %

Water→OilGas→OilMiscible

Vertical Sweep Effi ciency: The Vertical Sweep Effi ciency refers to the fraction of vertical section (or cross-section) of reservoir that is swept at a given pore volume throughput of displacing fl uid. This is function of the heterogeneity of the system (e.g. stratifi cation), the fl uid displacement process (e.g. waterfl ooding, gas injection) and the balance of forces (e.g. importance of gravity). It is shown schematically in Figure 27.

Figure 26Areal sweep effi ciency at breakthrough in a fi ve spot pattern for various displacement processes

Figure 25 Schematic of areal sweep effi ciency

25Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Good Vertical Sweep

Poor Vertical Sweep(By gravity over-ride or the presenceof a high-k streak in this case)

1.7 Terms Used in Numerical Reservoir SimulationMass Conservation: This is a general principle which is used in many areas of computational fl uid dynamics. It says that:

(mass fl ow rate into a block) - (mass fl ow rate out) = (the rate of mass accumulation in that block)A reservoir simulation model (for 1, 2 or 3 phases) is basically: A mass conservation equation combined with Darcy’s law.

Black Oil Model: Different types of formulation of the transport equations for multiphase/multicomponent fl ow are used to simulate the various recovery processes; by far the most common is the “Black Oil Model” which can simulate primary “Black Oil Model” which can simulate primary “Black Oil Model”depletion and most secondary recovery processes. A black oil simulation model is one of the most common approaches to modelling immiscible two and three phase (o, w, g) fl ow processes in porous media; it treats the phases rather like components; it does not model full compositional effects; instead, it allows the gas to dissolve in the other two phases (described by Rso and Rsw); however, no “oil” is allowed to enter the gas phase.

Grid Structure: This refers to the geometry of the grid being used in the numerical simulation of the system. This grid may be Cartesian, radial or distorted and may be 1D, 2D or 3D (see notes).

Spatial Discretisation: This is the process of dividing the grid in space into divisions of Δx, Δy and Δz. In reservoir simulation, we always “chop up” the reservoir into blocks as shown in the gridded examples below and then we model the block →block fl ows.

Figure 27 Schematic showing vertical sweep effi ciency

26

Glossary of Terms

Temporal Discretisation: This is the process of dividing up the time steps into divisions of Δt.

2D Areal Grid: This is a 2D grid structure as shown in Figure 28 which is imposed looking down onto the reservoir. For a Cartesian system, it would divide up the x and y directions in the reservoir into increments of Δx and Δy.

W1

W2

W3

y

x

∆x

∆z

∆y

Just 1 x z-block in 2D Areal Grid

2D Cross-Sectional Model: This is a 2D grid structure which is imposed on a vertical slice down through the reservoir. For a Cartesian system, it would divide up the x and z directions in the reservoir into increments of Δx and Δz. Cross-sectional calculations are carried out to asses the effects of vertical stratifi cation in the system and to generate pseudo-function for upscaling. (Figure 29).

3D Cartesian GridThe 3D Cartesian Grid is the most commonly used grid when constructing a relatively simple model of a reservoir or a setion of a reservoir. This is shown in Figure 30.

Figure 29

Figure 28Perspective view of a 2D areal (x/y) reservoir simulation grid: W = well

27Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Water Injector

Producer

∆x

∆y

∆z

(Variable)

Transmissibility: The transmissibility between two grid blocks is a measure of how easily fl uids fl ow between them. The mathematical expression for two phase fl ow between grid blocks i and (i+1) is (for water):

Block i Block i+1

Sw i Qw Sw i+1

krw i (kA)i krw i+1 (kA) i+1

(i+1/2) Boundary

Q k

kB xwQ kwQ k irw

w wBw wBi

Q k=Q k( )Q k( )Q kA( )A

( )P P( )P Pi i( )i iP Pi iP P( )P Pi iP PP P−P P( )P P−P P

∆++

i i( )i i+i i( )i iP Pi iP P( )P Pi iP P+P Pi iP P( )P Pi iP P1 2

1 2

i i( )i i1i i( )i iP Pi iP P( )P Pi iP P1P Pi iP P( )P Pi iP P/1 2/1 2

/1 2/1 2

.µ

where the inter-grid block quantities are averages at the interfaces (where i+1/2 denotes this block to block interface. The single phase Transmissibility, Ti+1/2, Ti+1/2, T , is given by:

T

xiTiT i+

+=( )kA( )kA

∆1 21 2

/1 2/1 2/1 2/1 2

and the full Water Transmissibility, Tw,i+1/2, Tw,i+1/2, T , between the two grid blocks is given by:

T

xk

BT

kBw iTw iT i rw

w w i

iTiT rw

w wBw wBi

, /w i, /w i/

/

/

/

., /+, /+

++

+

=( )kA( )kA

∆

=

1 2, /1 2, /

1 2/1 2/

1 2/1 2/

1 2/1 2/

1 2/1 2/µ µBµ µBw wµ µw wBw wBµ µBw wB

iµ µ

i /µ µ

/

/µ µ/

+µ µ

+µ µµ µ µ µµ µ1 2

µ µ1 2/1 2/

µ µ/1 2/

Figure 31

Figure 30A 3D Cartesian grid for reservoir simulation

28

Glossary of Terms

Therefore, we may write:

Q Tw wQ Tw wQ T i i i= −Q T= −Q T + +i i+ +i i, /i i, /i i= −, /= −i i+ +i i, /i i+ +i i( )P P( )P Pi i( )i iP Pi iP P( )P Pi iP Pi( )iP PiP P( )P PiP P= −( )= −P P= −P P( )P P= −P P+ +( )+ +P P+ +P P( )P P+ +P Pi i+ +i i( )i i+ +i iP Pi iP P+ +P Pi iP P( )P Pi iP P+ +P Pi iP P1 2i i1 2i i= −1 2= −i i+ +i i1 2i i+ +i i, /1 2, /i i, /i i1 2i i, /i i= −, /= −1 2= −, /= −i i+ +i i, /i i+ +i i1 2i i+ +i i, /i i+ +i i 1( )1( )P P( )P P1P P( )P PP P= −P P( )P P= −P P1P P= −P P( )P P= −P P

The water transmissibility is clearly made up of two parts each of which is an average between the blocks. The single phase part is (k.A)av and the two phase part is [krw/(μw.Bw)]av

(k.A)av - a Harmonic Average between blocks is taken for the single phase part of the transmissibility (see Chapter 4; Section 3.2).

[krw/(μw.Bw)]av - this term is more complicated. For the average relative permeability term, [krw]av an Upstream Weighting is used; For [(Upstream Weighting is used; For [(Upstream Weighting μw.Bw)]av the Arithmetic Average between blocks is taken. (See Chapter 4; Section 3.3).

Numerical Dispersion: The spreading of a fl ood front in a displacement process such as waterfl ooding, which is due to numerical effects, is known as Numerical Dispersion. It is due to both the spatial (Δx) and time (Δt) discretisation or truncation error that arises from the gridding. This spreading of fl ood fronts tends to lead to early breakthrough and other errors in recovery. How bad the error is depends on several factors including the actual fl uid recovery process being simulated e.g. waterfl ooding, water-alternating-gas (WAG) etc. (See Chapter 4; Section 2.2).

Grid Orientation: The Grid Orientation problem arises when we have fl uid fl ow both oriented with the principal grid direction and diagonally across this grid as shown schematically in Figure 32. Numerical results are different for each of the fl uid “paths” through the grid structure. This problem arises mainly due to the use of 5-point difference schemes (in 2D) in the Spatial Discretisation. It may be alleviated by using more sophisticated numerical schemes such as 9-point schemes (in 2D).

II

I = InjectorP = Producer

PP

PP

Local Grid Refi nement: Local Grid Refi nement is when the simulation grid is Local Grid Refi nement is when the simulation grid is Local Grid Refi nementmade fi ne in a region of the reservoir where (LGR) quantities (such as pressure or saturations) are changing rapidly. The idea is to increase the accuracy of the simulation in the region where it matters, rather than everywhere in the reservoir. E.g. LGR ==> close to wells or in the fl ood pilot area but coarser grid in the aquifer.

Figure 32Flow arrows show the fl uid paths in oriented grid and diagonal fl ow leading to grid orientation errors

29Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Hybrid Grid LGR: Hybrid Grids are mixed geometry combinations of grids which are used to improve the modelling of fl ows in different regions. The most common use of hybrid grids are Cartesian/Radial combinations where the radial grid is used near a well. Hybrid Grid LGR can be used in a similar way to other LGR scheme.

Examples: A simple example of LGR and Hybrid Grid structure is shown in fi gure Hybrid Grid structure is shown in fi gure Hybrid Grid33.

Coarse Gridin Aquifer

Hybrid Grid

Producer

Injector

Distorted Grids: A Distorted Grid is a grid structure that is “bent” to more closely Distorted Grid is a grid structure that is “bent” to more closely Distorted Gridfollow the fl ow lines or the system geometry in a particular case.

Corner Point Geometry: In some simulators (e.g. Eclipse), the option exists to enter the geometry of the vertices of the grid blocks. This allows the user to defi ne complex geometries which better match the system shape. This option is known as Corner Point Geometry and it requires that the block → block transmissibilities are modifi ed accordingly.

The idea of Corner Point Geometry is illustrated schematically in fi gure 34:

Figure 33Schematic of local grid refi nement (LGR)

30

Glossary of Terms

Coordinates ofVertices ( ) Specified

Block ( ) centres

Block <-> BlockTransmissibiltyHighly Distorted Grid Blocks

Fault

Distorted Grid

Corner Point Geometry

L1

L1

L2

L2

L3

L3L4

L4

Figure 34Grid structures for Faults and Distorted Grids

31Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

1 Extented Refinement

2 Imbedded Refinement (Rectangular)

3 Variable Refinement (Radial)

4 Hybrid (Radial in Rectangular) Local Grid Refinement Around Vertical Wells

5 Hybrid Local Grid Refinement (Horizontal Wells)

Figure 35Types of local Grids

32

Glossary of Terms

History Matching: History Matching in numerical simulation is the process of adjusting the simulator input in such a way as to achieve a better fi t to the actual reservoir performance. Ideally, the changes in the simulation model should most closely refl ect change in the knowledge of the fi eld geology e.g. the permeability of a high perm streak, the presence of sealing faults etc. The observables which are commonly matched are the fi eld and individual well cumulative productions, watercuts and pressures.

Examples: Examples of history matching of pressure and water-oil-ratio (WOR) in two reservoirs are Figure 36. Note that in the WOR match the “fi rst pass” was very inaccurate but that eventually a suitable match was found. A vitally important point is that a good history match must be obtained for the right reason. It may be possible to get a satisfactory match for the wrong reason i.e. by adjusting a variable that is not the primary cause of the mis-match (indeed, this is very often the case). However, such a model will eventually have very poor predictive properties.

Final Match

CalculatedField Data

First Trial

Observed Data

Time, Days x 10

Wat

ercu

t

1.0

0.8

0.6

0.4

0.2

0.00 1 3 5 7 9 11

Year

Pre

ssur

e (p

si)

3600

3400

3200

3000

2800

2600

2400

2200

20000 1 2 3 4 5 6 7 8 9 10 11 12

(a)

CalculatedField Data

Year

Pre

ssur

e (p

si)

3600

3400

3200

3000

2800

2600

2400

2200

20000 1 2 3 4 5 6 7 8 9 10 11 12

(b)

CalculatedField Data

Year

Pre

ssur

e (p

si)

3600

3400

3200

3000

2800

2600

2400

2200

20000 1 2 3 4 5 6 7 8 9 10 11 12

(c)

Final Pressure Matches of Typical Khursaniyah Field Wells:(a) Reservoir AB(b) Reservoir C(c) Reservoir D (MP)

Initial and Final Matches of WOR of a Well in aHighly Stratified Reservoir

1.8 Numerical Solution of the Flow Equations in Reservoir SimulationFinite Differences: When the derivative in a differential equation is approximated as a difference equation as follows:

Figure 36A fi eld of a history match of watercut and well pressures; redraw from Mattax and Dalton (1990)

33Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

∂∂

≈ ( )

∆( )−( )S

x( )S S( )−( )−S S−( )−

xi

( )i i( )( )S S( )i i( )S S( )( )1( )

then this is referred to as a Finite Difference approximation. In this example, which is illustrated below, (∂S/∂x)i is the derivative of Saturation (S) with respect to x at grid point i ; Si and Si-1 are the discrete values of S at grid points i and i-1, respectively; Δx is the size of the spatial grid.

Slope = Slope = ∂s∂∂x i

SSi-1

SSi

SSi+1

∆x ∆x ∆x ....x ....

i-1 i+1ix

S(x

,t)

Linear Equations: When fi nite difference methods are applied to the differential equations of reservoir simulation, a set of linear equations results. These have the form:

A. x bx b=x b

where A is a matrix of coeffi cients, x is the vector of unknowns and b is the (known) “right hand side”. Expanded up, this set of linear equations has the form:

a11 x1 + a12 x2 + a13 x3 .... + a1n xn = b1a21 x1 + a22 x2 + a23 x3 .... + a2n xn = b2a31 x1 + a32 x2 + a33 x3 .... + a3n xn = b3a41 x1 + a42 x2 + a43 x3 .... + a4n xn = b4

............an1 x1 + an2 x2 + an3 x3 .... + ann xn = bn

Direct Solution Of Linear Equations: A Direct Solution method is when the linear equations are solved by an algorithm which has a fi xed number of operations (given fi xed number of operations (given fi xedN, the number of linear equations [unknowns]). If the equations have a solution, then, in principle, a direct method will give the exact answer, x(true), to the machine accuracy. E.g. Gaussian Elimination

Iterative Solution Of Linear Equations: An Iterative Solution method is when the linear equations are solved by an algorithm which has a variable number of operations. A fi rst estimate of the solution vector x(0) is made and this is successively refi ned to converge to the true solution. In a convergent iterative method, then x(v) → x(true) as v → ∞. It is because of this iterative process that a variable number of steps may

Figure 37

34

Glossary of Terms

be required depending on how accurate the answer must be. Normally, the iterative method would be carried out until:

| x(v) - x(true)| < Tol.

where Tol. is some small pre-specifi ed tolerance. E.g. Line Successive Over-relaxation (LSOR)

Grid Ordering Schemes: When the simulation grid blocks are ordered in various ways, the structure of the non-zeros in the sparse matrix, A, is different. Advantage can be taken of the precise structure when solving these equations. E.g. Schemes known as D2 and D4 ordering.

1.9 Pseudo-Isation and UpscalingUpscaling: The process of reproducing the results of a calculation which is carried out on a “fi ne grid” on a coarser grid is known as Upscaling. The basic idea of upscaling is shown schematically in Figure 38. The input properties at the coarser scale must take into account the fl ow effects of the smaller scale structure. These coarser scale properties then become pseudo-properties.

35Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

High Sw

Low Sw

Oil

Fine Grid Layered Model

Upscaling or Pseudo-Isation

Coarse Grid Layered Model

Fine GridCoarse Grid

Time

Oil Recovery

% O

OIP

Pseudo-Property: This refers to the value of a property or function (e.g. permeability, relative permeability..) which is an average or effective value at a certain scale - usually the grid block scale. For example, we might put the value kx = 150 mD in a simulator grid block which is 200 ft x 200 ft x 30 ft. Clearly, this incorporates a large amount of geological substructure and permeability may vary very signifi cantly in different parts of this block.

Pseudo-Relative Permeability: This is probably the most important pseudo-property that is used in reservoir simulation. It refers to the effective relative permeability in the simulation model at the grid block scale and is shown schematically in Figures 39 and 40. It must incorporate the effects of all the smaller scale geological heterogeneity, the balance of forces (viscous/capillary/gravity) and certain numerical effects (numerical dispersion). Methods for calculating the Pseudo-rel perm include: Jacks et al, Kyte and Berry, Stone etc. Newer methods are based on tensor pseudo-relative permeabilities (Pickup and Sorbie, 1994).

Figure 38Basic idea of upscaling

36

Glossary of Terms

Geopseudos: When the fl uid fl ow upscaling is performed in the correct context of the sedimentary structure up from the lamina, laminaset, bedform.. scales, then the approach is known as the Geopseudo Methodology. This has been developed in work at Heriot-Watt which has extended more conventional approaches by “putting in the geology”.

Figure 40 shows a simple example of a pseudo relative permeability showing “holdup of fl uid”.

Fine Grid Layered Model

Upscaling or Pseudo-Isation

Coarse Grid Layered Model

Fine GridCoarse Grid

Time

Oil Recovery

% O

OIP

krel

Sw

krel

Sw

"Rock"Relative Permeabilities

Pseudo-RelativePermeabilities

High Sw

Low Sw

Oil

Figure 39Basic idea of upscaling or pseudo-isation

37Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Sor

Sw

Sw

Sor

Swc

Swc

Water Flow

No Water Flow

krokrw

Sw

Rel Perms.

Rel Perms. ?

1.10 Numerical Simulation of Flow in Fractured SystemsFractured System: In this context, we imply systems (such as in many carbonate reservoirs) where small scale conductive fractures occur but most of the oil is in the rock matrix. In certain non-porous fractured rock reservoirs (e.g. fractured volcanics), it is possible to have all the oil in the fractures but these are much less common.

Typically, in porous fractured systems: fracture porosity, φf = 0.1 - 1% of bulk volume f = 0.1 - 1% of bulk volume f(i.e. as a fraction φf = 0.001 - 0.01).f = 0.001 - 0.01).f

Features of Fracture Geometry: The main geometric features of fractures which are thought to affect fl uid fl ow are the: fracture orientation, width, conductivity, connectivity and spacing (or fracture density). The “interface” between the fracture and the matrix will also play a very important role in multiphase fl ow and fl uid displacement processes.

Stylolites: Stylolites are frequently found in limestones. They are laterally extensive features formed by grain-to-grain sutured contact caused by the phenomenon of pressure solution. These features may signifi cantly reduce vertical permeability thus causing systems containing them to have very low (kv/kh) ratios (at certain scales).

Vugs: Vugs are dissolution “holes” in a carbonate rock caused by diagenetic reactions.

Dual Porosity Models: These are the most widely used simulation models for modelling fl ow in fractured systems. They have separate conservation/fl ow equations for the matrix and the fractures and matrix → fracture fl ow is represented by Transfer Functions. They are most frequently used to model multiphase fl ow in fractured carbonates.

Variants of this model allow for; (i) fl ow only in fractures and (ii) fl ow in both fractures and matrix.

Discrete Models of Fracture Systems: A more recent approach to fl ow in fractured systems tries to represent the fractures explicitly as oriented planes with various shapes in 3D. Single phase (tracer) fl ow models of this type are used to model radio-

Figure 40A simple example of a pseudo relative permeability

38

Glossary of Terms

nuclide transport in fractured media. However, multi-phase models of this type are not commercially available at present.

Transfer Function: The function which describes the oil fl ow rate between the matrix and the fractures is known as the Transfer Function. Approximate analytical equations for this function have been suggested by Birk, Boxerman and Ahronovsky.

Sudation: When oil is recovered from the matrix blocks in a fracture by a combination of gravity and capillary forces, the recovery mechanism is sometimes referred to as Sudation.

1.11 Miscellaneous-Vertical Equilibrium, Miscible Displacement and DispersionVertical Equilibrium: The concept of Vertical Equilibrium (VE) is quite widely used in reservoir engineering. It takes several forms, two of which are listed below (and illustrated schematically in Figure 41:

A: the pressure gradients in a particular direction (x, say), ∂P/∂x, are all equal locally in a long system. See Figure 41a.

B: there is virtually instant crossfl ow vertically - nearly infi nite - compared with the horizontal fl ow. See Figure 41b.

The VE assumption is often made in order to simplify the mathematical analysis of certain fl uid fl ow problems in reservoir engineering.

Vertical Equilibrium (VE) is known to apply in “long thin” systems (where Δx >> Δz, in Figure 41b). More accurately, the VE limit is approached as the scaling group, RL → ∞ ; where:

R

xz

kkL

z

x

= ∆∆

./1 2/1 2/

and kz and kx are the vertical and horizontal permeabilities, respectively. In practice, if RL is > 10, then VE is a very good assumption.L is > 10, then VE is a very good assumption.L

39Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

∆z

∆z

∆x

∆x

A: Equality of Layer Pressure Gradients (Where ∆x >> ∆z)

B: Instantaneous/Infinite Vertical Crossflow

Layer 1

Layer 2

Layer 3

∂P∂x 1

∂P∂x 2

∂P∂x 3

Miscible Displacement: Whereas oil and water are immiscible fl uids (i.e. they do not mix and are separated by an interface), some fl uids are fully Miscible (i.e. they mix freely in all proportions). When a gas (or other fl uid) is injected into an oil reservoir and the fl uids are miscible, this is referred to as a Miscible Displacement. When two fl uids (e.g. gas and oil) are fully miscible (σgo = 0), the local pressure and the pressure gradients are the same (there is no capillary pressure since there is no interface).

The mixing between the solvent and the oil can occur locally by Dispersion and by Fingering (see Fingering (see Fingering Viscous Fingering below). The displacement is described by a Viscous Fingering below). The displacement is described by a Viscous Fingeringgeneralised Convection-Dispersion Equation where the mixing viscosity, μ(c) is a function of the concentration of the solvent, c (or oil). Often, the solvent viscosity is below that of the oil (i.e. μs < μo) which tend to cause an instability to develop in the displacement known as Viscous Fingering.

The Miscible Flow Equations: These comprise of a Pressure Equation and a Transport Equation. The pressure equation is derived by inserting Darcy’s Law (with a viscosity dependent on solvent concentration) into the continuity equation. The transport equation is a generalised convection-dispersion (or convection-diffusion) equation.

Continuity equation:

∇ =∇ =.u∇ = 0 (assuming incompressible flow)

Darcy Equation:

uk

P= −( )c( )c

∇P∇Pµ

. P. P∇. ∇P∇P. P∇P

where u is the Darcy velocity, c is the miscible solvent concentration and k is the

Figure 41Schematic views of vertical equilibrium

40

Glossary of Terms

permeability tensor.

The pressure equation is then given by:

∇ = −∇

( )∇

∇( )

∇

. .∇ =. .∇ = −∇. .−∇ . ˜

. .( )

. .( ). . ˜

∇ =u∇ =∇ =. .∇ =u∇ =. .∇ =k( )c( )

P qP q∇P q∇

P q

P q

P q

P q

P q

=P q= ˜P q̃

k( )c( )

P q∇P q∇

P q

P q

P q

P q

P q

= −P q= − ˜P q̃

µ( )µ( )

µ( )µ( )

or

where q̃ represent any source/sink terms

The transport equation is the generalised convection-dispersion (diffusion) equation:

∂∂

= ∇ ( )( )∇( )∇ − ∇c

t( )D c( )∇( )∇D c∇( )∇ c= ∇ = ∇ − ∇ − ∇v − ∇v − ∇cv c. .( ). .( )( )D c( ). .( )D c( ) − ∇.− ∇− ∇v − ∇.− ∇v − ∇

where D is the dispersion tensor and v is the pore velocity ( v v v =v uφ

).

Dispersion and Dispersivity: Hydrodynamic dispersion in a porous medium at the small (core) scale is a frontal spreading or mixing which is due to various fl ow paths which the fl uid can fl ow along at the pore scale. This mixing is a “diffusive” process since the growth of the mixing zone, Lf , tends to grow in proportion to t .In a tracer core fl ood experiment, the Dispersion Coeffi cient, D, may be measured by fi tting the effl uent profi le to an analytical solution of the Convection-Dispersion Equation (see fi gure 42). Units of D (cm2/s - at lab scale).

Dispersive mixing behaviour can also be seen from the “mixing” effect of heterogeneities at larger scales in a porous medium. D, has been found to depend linearly on velocity through the relationship: D = α . v; where α is the Dispersivity and has dimensions of length. Dispersion is actually a tensor in rather the same way that permeability ( k ) in its general form is a tensor.

41Institute of Petroleum Engineering, Heriot-Watt University

Glossary of Terms

Figure 43Experimental demonstration of viscous fi ngering

Figure 42Schematic illustration of dispersion and the convection-dispersion equation for simple tracer fl ow

Lf

DispersiveMixing Zone Effluent

ConcentrationCe(1,t)C(x,t1)

time (pv)

Ce 1

C

0 1x1

1

In situ concentration profile at time, t1; C(x,t1)

Described by Convection Dispersion Equation:

C = Dimensionless Concentration (C/Co)D = Dispersion Coefficientv = Pore Velocity (Q/Aφ)

∂C∂t

∂C∂x

∂2C∂x2= D - v

Viscous Fingering: When a high mobility (lower viscosity) fl uid displaces a lower mobility (higher viscosity) fl uid, a type of instability may develop known as Viscous Fingering. For such a displacement, the Mobility Ratio (see above) is high and the process may be observed in either miscible or immiscible displacements, although it occurs more readily in miscible systems. Results from an experiment are shown in Figure 43 where the dark fl uid is high viscosity and the light fl uid is low viscosity. Clearly, viscous fi ngering leads to a poorer sweep effi ciency in such fl oods.