controle motor de passo microcontrolador

Transcript of controle motor de passo microcontrolador

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 1/28

MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

MIE443- Dispensing Robot Prototype

TECHNICAL MANUAL AND DATA SHEET

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 2/28

1 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

TABLE OF CONTENTS

1| SYSTEM SPECIFICATIONS

2| MECHANICAL SPECIFICATIONS

2.1 MACHINE OVERVIEW

2.2 HORIZONTAL AXIS DRAWINGS

2.3 VERTICAL AXIS DRAWINGS

2.4 FLUID DISPENSING SYSTEM

3| ELECTRICAL SPECIFICATIONS

3.1 ELECTRICAL COMPONENTS

3.1.1 MICROCONTROLLER DRAWINGS AND SPECIFICATIONS

3.1.2 STEPPER MOTOR CONTROLLER BOARD DRAWINGS

3.1.3 STEPPER MOTOR SPECIFICATIONS

3.1.4 PUMP MOTOR SCHEMATICS

3.1.5 SENSOR CIRCUIT SCHEMATICS

3.1.6 POWER SUPPLY UNIT

3.2 ELECTRICAL CHARACTERISTICS

4| CONTROL SYSTEM

4.1 CONTROL SYSTEM OVERVIEW

4.2 COMMUNICATION SPECIFICATIONS

4.3 EXECUTION OF SAMPLE PROGRAM

5| PROTOTYPE ANALYSIS AND FUNCTIONALITY

6| FUTURE DEVELOPMENT

6.1 CHANGES TO MECHANICAL SYSTEM

6.2 CHANGES TO ELECTRICAL SYSTEM

6.3 CHANGES TO CONTROL SYSTEM

6.4 DEVELOPMENT OF PROGRAM INTERFACE

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 3/28

2 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

This document contains specific technical data about the robotic fluid dispenser prototype. Its purpose

is to give the reader a better understanding about the details of individual devices and how the system

operates. For a better description of the dispenser capabilities for your particular application refer to the

product manual.

1| SYSTEM SPECIFICATIONS

The Dispensing Robot Prototype is a compact model that was designed for testing of this system and

establishing performance and capability. A modular product line is intended to be created from these

results with the prototype robot as the base system and benchmark for improving or modifying

performance and functionality. The prototype has the following features:

Dispensing area X/Y/Z 9.5”(241mm) / 10”(254mm) / 5.8”(147mm)

Resolution 0.01” processing capability (0.0008” mechanical capability)

Translation speed X/Y 3.75”/min (@ 22.5 RPM) per axis

Drive system 4 Phase Stepping motors (1.8° resolution)/6 tooth per inch

Machine Dimensions 18”x 18.5”x 19” envelope sizeFlow control 0.6mL to

Pump/tubing Peristaltic pump/ 1.6mm silicone tubing

Dispense modes Point dispense and continuous path

Path motion Linear and arc

User interface User command input; input generation from CAD software

Processor 8-bit microcontroller

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 4/28

3 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

2| MECHANICAL SPECIFICATIONS

2.1 MACHINE OVERVIEW

The overall envelope of the dispenser prototype, including mounted electronics is 18”x 18.5”x H 19”

Structure and Mechanism Overview

Figure 2.1: Overall Mechanical Assembly (dimensions in inches)

The dispenser prototype frame and sub-assemblies

are custom manufactured almost entirely from

aluminum 1”x1” angle stock and ¼” aluminum

plate.

Translation is accomplished using three mutually

perpendicular lead screws driven by stepping

motors. Lead screws are Ø ¾“ 6 tooth per inch

ACME threaded rods and are mated to a nut oneach moving component. The moving sub assemblies are supported using a rail and roller system to

relieve any stress on the lead screws and ensure minimal backlash in the translation system. A motor

resolution of 200 steps per revolution allows the mechanism to be capable of 0.0008” dimensional

resolution on each axis. The mechanical system allows for 9.5” by 10” of linear translation of the

dispenser nozzle in the X and Y axis respectively and 5.8” of vertical displacement.

Descriptions

1 Y-axis feed screw; 14”x Ø ¾“ 6TPI

ACME threaded rod

2 X-axis step motor; Lin Engineering

5718M-05S-05 (see Section 3.1.3)

3 Vertical axis assembly (see

section 2.3)

4 X-axis assembly (see Section 2.2)

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 5/28

4 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

All electronics are mounted on an acrylic mounting panel on the side of the frame that provides easy

access to debugging modification.

2.2 HORIZONTAL AXIS DETAILS

Figure 2.2: X-Axis Sub-Assembly Drawing (dimensions in inches)

The x-axis sub assembly is supported by the four

polyurethane rollers that mate with rails mounted

parallel to the y-axis lead screw on both sides of the

fame. This sub-assembly contains the x-axis

translation motor and lead screw, along with the rail

system for supporting the vertical axis mechanism. All

components are housed compactly to hang below theframework to avoid interference with the y-axis lead

screw.

The pump and drive motor are mounted on the

outside rails of this assembly along with the fluid

reservoir.

Descriptions

5 X-axis feed screw; 14”x ؾ“ 6TPI

ACME threaded rod

6 ACME nut; mates with Y-axis feed

screw

7 X-axis step motor; Lin Engineering

5718M-05S-05 (see Section 3.1.3)

8 Ø1.25”x Ø0.5”x0.5” feed screw

bearing

9 Polyurethane rollers

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 6/28

5 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

2.3 VERTICAL AXIS DETAILS

Figure 2.3-A: Vertical Axis Sub-Assembly Drawing (dimensions in inches)

The nozzle is mounted on a bracket extending from the cart that mates with the vertical lead screw. The

nozzle can be raised to obtain clearance from any objects on the work area.

2.4 FLUID DISPENSING SYSTEM

A micro peristaltic pump from Williamson Manufacturing is implemented to achieve fluid dispensing.

The pump is coupled to a DC motor (see Section 3.1.4) geared down to achieve the torque necessary to

drive the pump. Implementation of a peristaltic pump allows for versatility for pumping different fluids.

The fluid does not contact the roller mechanism preventing contamination of the fluid dispensed, and

cured silicone tubing allows for safe dispensing of chemicals.

Descriptions

6 ACME nut; mates with X-

axis feed screw

8 Ø1.25”x Ø0.5”x0.5” feed

screw bearing

9 Polyurethane rollers

10 Z-axis feed screw;

8”x ؾ“ 6TPI ACME

threaded rod

11 Z-axis step motor;

Howard Ind. 1-19-4202

(see Section 3.1.3)

12 Dispenser nozzle

This sub-assembly hangs from the

x-axis sub assembly. The vertical

lead screw and housing are

contained within a compact

package to minimize interference

with the structure and are

supported from the cart that sits

within the x-axis sub-assembly.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 7/28

6 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

Figure 2.4: Peristaltic Pump Head

Tubing 1.6mm ID cured silicone

Rollers 4 ground stainless steel

Flow 0.1 mL per revolution; max 15mL/min at

150 RPMWith proper motor control this pump system can

dispense volumes to 0.05 mL. The pump provides

enough power to use with up to 16 feet of tubing

between nozzle and reservoir and can be run dry for

cleaning and priming.

The dispensing system holds fluid in a 50 mL refillable

reservoir attached to the x-axis cart. The supply line can

be connected to an auxiliary source using a 1.6mm

tubin connector.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 8/28

7 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

3| ELECTRICAL SPECIFICATIONS

3.1 ELECTRICAL COMPONENTS

The following parts compose the electrical system of the dispenser:

PIC16F887 8-bit microcontroller; mounted on ETT BASE PIC 40 controller board

(3) Stepper motor controller printed circuit boards

(2) Lin Engineering 5718M-05S-05 1.8° High-Torque Step Motor

Howard Industries 1-19-4202 3.6° Step Motor

Tamiya RC-260 DC motor

DC (pump) motor control circuit

(3) Photointerupter Sensors

Photointerrupter buffer circuit

450W ATX PC power supply

3.1.1 MICROCONTROLLER DRAWINGS AND SPECIFICATIONS

The communications and control of all systems is handled by a PIC16F877 microcontroller mounted on

the ETT BASE PIC 40 controller board. The controller board has been modified to allow for programming

and serial interfacing using the PICkit2 programmer/debugger.

Figure 3.1-A: Microcontroller Board Layout

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 9/28

8 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

CONTROLLER BOARD LAYOUT DESCRIPTION

1 Power connection. Mini-Molex from Power supply

(5V red; GND black)

2 PIC16F877 Microcontroller, 40 pin DIP

3 RB Signal Port I/O

4 RD Signal Port I/O5 RC Signal Port I/O

6 RA Signal Port I/O

7 RS-232 Serial communication port (not used)

8 PICkit2 programming port*

9 PICkit2 UART port*

10 5VDC supply and GND reference

11 Power LED

12 Reset push button

*See figure on right for proper connection of PICkit2 programmer

PICKIT2 PORT CONNECTION SPECIFICATIONS Pin Programming Port UART Port

1 VPP/MCLR (PIC16 pin 1) No Connection

2 VDD (5 VDC) VDD (5 VDC)

3 VSS (Ground) VSS (Ground)

4 RB7/Program Data (PIC16 pin 40) RX (Connected to RC6/TX, pin 25 on PIC16)

5 RB6/Program Clock (PIC16 pin 39) TX (Connected to RC7/RX, pin 26 on PIC16)

6 No Connection No Connection

MICROCONTROLLER SPECIFICATIONS

PIC16F877 8-Bit CMOS Flash Microcontroller

Operating Frequency 10MHz

(External Oscillator)

I/O Pins 28

Program Memory 8K

EEPROM Data Memory 256 bytes

PWM Modules 2

Communications USART, MSSP, PSP

Figure 3.1-B: Port Diagrams

Figure 3.1-C: PIC16F877 Pin Diagram

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 10/28

9 MIE443 DISPENSING ROBOT PROTOTY

3.1.2 STEPPER MOTOR CONTROLLER

DIMENSIONS: 4”x 3 ¼“ (max)

DESCRIPTION

The board is designed around the

and controls one stepper motor.

(bottom) with all through-hole co

received from the microcontroller

circuit allows each stepper to be

pulse to the CLOCK pin. The circuit

simplifying the motor control proc

via the printed traces and are not

to Figure 3.1-E on the next page fo

INPUT/OUTPUT

PinVCC Controll

VSS Stepper

GND Common

DIR DIRECTI

CLK CLOCK in

SYNC L297 syn

A,B,C,D Output t

Figure 3.1-D: Stepper Motor Controller B

*See Section 3.2 for stepper motor volt

**See the next page for descriptions o

E TECHNICAL MANUAL AND DATA SHEET

COM

Na

IC1

IC2

R1†

C1†

R2

R3,

R5,

R7

C2

R8

C3,

C5,

LED

LED

LED

D4-

D15

† No

net

only

the

cont

the

the

at th

DRAWINGS

297/L298 stepper motor controller circuit,

he board has traces printed on one side

ponents mounted on the top. Inputs are

via the CLOCK and DIRECTION pins. The

advanced by one step by sending a single

generates the motor coil phase sequence,

ss. Note that all connections are not made

shown on the above diagram. Please refer

schematics to connect all wiring.

Descriptionr circuit power supply ( 5V)

otor power supply*

ground

N control input**

put**

chronization terminal**

o motor connections

ard (Top)

ages

pin functionality

PONENTS

e Description

L297Stepper

Motor

Controller

L298 Dual

Full-Bridge

Driver

22k

3.3nF

100k

4 1Ω (2W)

6 560Ω

10k

TrimPot

100nF

560Ω

4 100uF

6 100nF

, Bi-Colour

LED

5mm LED

3A 1000V

Schottky

Diode

te that the RC

ork (R1, C1) is

implemented on

-axis motor

rol board. On

ther two boards

297 is grounded

e OSC pin.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 11/28

10 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

Figure 3.1-E: Stepper Motor Controller Circuit Schematics

Pin Function

L297

(19) HALF/FULL High input on this pin selects half-stepping mode. Low input selects Full Step

mode.(10) ENABLE Low input disables the stepper controller chip.

(16) OSC RC oscillator network. Only implemented on the X-axis controller board.

(17) CLOCKWISE/CCW Direction control input. High input selects clockwise stepping sequence.

(18) CLOCK Step clock. Low pulse on this pin advances the motor one step.*

(1) SYNC Oscillator output. Sync pins on each board are connected together.

(4) A Motor phase A drive signal.

(6) B Motor phase B drive signal.

(7) C Motor phase C drive signal.

(9) D Motor phase D drive signal.

L298

(4) VS Power supply.(2) OUT1 Output to motor winding A. Active when INPUT1 is high.

(3) OUT2 Output to motor winding B. Active when INPUT2 is high.

(13) OUT3 Output to motor winding C. Active when INPUT3 is high.

(14) OUT4 Output to motor winding D. Active when INPUT4 is high.

*See section 4.2 for signal characteristics

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 12/28

11 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

3.1.3 STEPPER MOTOR SPECIFICATIONS

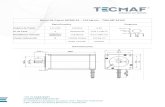

LIN ENGINEERING 5718M-05S-05 1.8° HIGH-TORQUE STEP MOTOR

One of these motors is used to drive each horizontal (X & Y) movement mechanism. The motor is a 2 coil

bipolar stepping motor with 1.8° step resolution (200 steps per revolution). The motor is driven in full

step mode to achieve highest operating speeds.

Figure 3.1-F: X & Y-Axis Step Motor Dimensions

SPECIFICATIONS

Operating Voltage 5VDC

Amps per Phase 1.40 A (max)

Hold Torque 173 oz-in (1.29 N-m)Operating speed* 3.75“ per min at 22.5 RPM

Resistance per Phase 3.6 Ω

* Maximum determined operating speeds for this application without missing steps under normal conditions. For

torque curves see data sheet at http://www.linengineering.com/line/contents/stepmotors/pdf/5718.pdf

MOTOR WIRING

Wire Colour

Connection on

motor controller

circuit

1 Red A

2 Blue B

3 Green C

4 Black D

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 13/28

12 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

HOWARD INDUSTRIES 1-19-4202 3.6° STEP MOTOR

This motor is used to drive the Z-axis mechanism. The motor is a 4 phase unipolar stepping motor with a

resolution of 3.6° per step (100 steps per revolution). The motor is operated in full step as a bipolar

motor with no connection to the common wire.

DIMENSIONS

Housing: 1.75” x 1.75” x 1.35”

Shaft: Ø 0.19” x 0.43”L

Specifications

Operating Voltage 12VDC

Amps per Phase 150 mA (max)

Hold Torque 67.6 oz-in (0.504 N-m)

Operating speed 2.1 “ per min at 12.6 RPM

Resistance per Phase 75 Ω

* Maximum determined operating speeds for this application without missing steps under normal conditions.

MOTOR WIRING

Wire Colour Connection on

motor controller

circuit

1 White A

2 Green B

3 Red C

4 Brown D

5 Black No Connection

3.1.4 PUMP MOTOR SCHEMATICS

The pump system is driven by a Tamiya RC-260 DC motor geared down through a series of planetary

gear boxes. The motor is controlled by the microcontroller using a simple MOSFET switch circuit which

drives the motor in one direction only. The control circuit allows for future implementation of PWM

when feedback loop can be implemented from the pump encoder for precise fluid flow rate control.

DC MOTOR SPECIFICATIONS

Operating Voltage 3.3V

Motor Speed 10200 RPM (max)

Gear Ratio 40:1

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 14/28

13 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

MOTOR CONTROL CIRCUIT

Components Description

MOTOR RC-260 DC Motor

Q1 IRFZ34 HEXFET Power MOSFETR1 1.17 MΩ pull down resistor

R2 1 Ω 2 Watt resistor

D1 1N4001 Rectifying diode

PUMP Input from microcontroller, when high pump is on

Notes:

• Currently pump is driven with the MOSFET fully open/ fully

closed. Speed has been configured using 1Ω resistor to reduce

current to the motor. Circuit allows PWM to be implemented in

the future.

• Voltage collapse was affecting the power supply unit when the

pump was turned on causing instability in other circuits.

Rectifying diode is required to resolve this problem.

3.1.5 SENSOR CIRCUIT SCHEMATICS

Three photointerrupters are used to detect the zero position for each axis. When the sensor beam is

broken the circuit outputs a high signal to the microcontroller. The output of the sensors requires

passing through a buffer circuit to ensure the minimum voltage for a high reading on the microcontroller

is attained.

Figure 3.1-H: Photointerrupter and Buffer Circuit Schematics

Descriptions

OK1,

OK2

ON1120

Photointerrupter

OK3 TLP831

Photointerrupter

R1,R2,

R3

330Ω

R4,R5,

R6

47K

R7 110K

R8 175K

VREF 1.93 VDC (Buffer

Reference Voltage)

ZERO_X Output to PIC16

ZERO_Y Output to PIC16

ZERO_Z Output to PIC16

Figure 3.1-G: DC Motor Driver

Schematic

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 15/28

14 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

3.1.6 POWER SUPPLY UNIT

The all components are powered using a modified ATX 450W PC power supply. The ‘Power On’(Green)

and ‘Power Good’(Grey) connections on the 24 pin connector that allow software to turn off the power

supply have been permanently connected resulting in the main switch to control power to the whole

system. All unnecessary connectors and wiring have been trimmed and hidden inside the power supplyhousing. Original large MOLEX four-pin connectors have been modified for use to power the stepper

circuit boards.

WIRING SPECIFICATIONS

Colour Signal

Red 5V

Yellow 12V

Orange (Grey) 3.3V

Black Ground

Figure 3.1-G: Power Supply Unit Back Panel

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 16/28

15 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

3.2 ELECTRICAL CHARACTERISTICS

MICROCONTROLLER

Characteristic Symbol MIN TYP MAX Units

Supply voltage VDD 4.5 5 5.5 V

Supply current IDD 7 15 mA

Current sourced by I/O ports 200 mA

Current sunk by I/O signal ports 200 mA

Input LOW voltage VIL VSS 0.8 V

Input HIGH voltage VIH 2.0 VDD V

Output LOW voltage VOL 0.6 V

Output HIGH voltage VOH VDD-0.7

External HC oscillator frequency FOSC 10 MHz

STEPPER MOTOR CONTROLLER BOARDS

Characteristic Symbol MIN TYP MAX Units

Logic circuit supply voltage VCC 4.75 5 7 V

Input signal LOW voltage VIL 0.6 VInput Signal HIGH voltage VIH 2.3 VCC V

Stepper motor supply voltage

X-axis

Y-axis

Z-axis

VSS 4.5

4.5

10

5

5

12

6

6

13

V

PUMP MOTOR CONTROLLER CIRCUIT

Characteristic Symbol MIN TYP MAX Units

Supply voltage 3.3 5 V

Enable input voltage PUMP 2.0 5 V

PHOTOINTERRUPTER CIRCUIT Characteristic Symbol MIN TYP MAX Units

ON1120 open beam output 0.1 V

ON1120 broken beam output 1.95 2.1 2.2 V

TLP831 open beam output 1.68 1.75 V

TLP831 broken beam output 1.87 2.03 2.05 V

Buffer reference voltage VREF 1.93 V

Buffered broken beam output 3.83 V

POWER SUPPLY

Characteristic Symbol MIN TYP MAX Units

Output Voltages5VDC (red)

12VDC (yellow)

3.3VDC (orange)

4.75

11.4

3.14

5

12

3.3

5.25

12.6

3.47

V

Output Currents

5VDC (red)

12VDC (yellow)

3.3VDC (orange)

30

25

25

A

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 17/28

16 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

4| CONTROL SYSTEM

4.1 CONTROL SYSTEM OVERVIEW

The control system is implemented to manage individual devices and monitor position output of the

dispenser. Instructions are received from an external device as sequences of 8-bit commands.Commands are encoded by software on the user’s computer and can be generated in real-time or

stored in a preprogrammed sequence. Once the dispenser receives the commands the instructions are

decoded and the control system ensures the commands are executed properly. For a detailed list of all

instructions and system outputs, see Section 4.2.

CONTROL SYSTEM ORGANIZATION

RECEIVE INSTRUCTION

When the system is waiting for a command to be issued it will remain idle. The system will wait until acommand byte is issued. Once a command byte is received the system will prompt for any additional

information necessary. Additional information the system requires may be coordinates of dispense

locations, line start and finish locations or z-axis height offset dimensions. Each byte received

(command, plus necessary values) is stored in a buffer while data transfer is taking place and for later

passing to the execute function. Once necessary information is received by the system to execute a

Z-Axis Step Motor

Control Circuit

Position Monitoring

Receive Instruction

Decode and Execute

Serial

Communications

Motor Output

Generation

X-Axis Step Motor

Control Circuit

Y-Axis Step Motor

Control Circuit

DC Pump MotorControl Circuit

Photointerrupter

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 18/28

17 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

command, the system closes the communications and any data transferred will result in a

misinterpreted command when the communications are initialized to receive the next command.

The communication system must be disabled while the microprocessor is executing a command. The

stepper motor speed control is based on an internal interrupt timer, and for proper functioning the

UART interrupts must be disabled. For this reason the current implementation only allows data transfer

while the system is idle.

DECODE AND EXECUTE

The command byte is first read to determine the subsequent steps to be executed. If no data bytes are

required the command is executed (i.e. return the dispenser to the origin). If the command requires

some dimensions or coordinates (i.e. point or line dispense) the data bytes are read from the buffer and

decoded into floating point numbers. For more information on the structure of the data bytes and

command bytes see Section 4.2.

The function then analyzes the current position and then calculates the required displacement of each

axis. These arguments are then passed to the motor control function to generate motor outputs.

MOTOR OUTPUT GENERATION

Using two timers, one for each horizontal axis, the motor output function determines the step rate of each motor from the start and end coordinates. One motor is always driven at maximum operating

speed while the other motor is driven at a fraction of that speed to generate direct point to point

movement or to generate the correct angle of the output line (i.e. for a line dispense starting at the

origin (0, 0) and ending at point (3.00”, 1.00”) the x-axis step output will be maximum speed while the y-

axis output will be at one third that speed)

The pump motor output is generated as a PWM signal when the execute function passes the

appropriate argument. The pump speed cannot be adjusted outside the microcontroller source code at

this time.

POSITION MONITORING

Monitoring the current position of the dispenser is almost entirely done as a virtual process. Every time

the motors are instructed to step, the motor step function adds or subtracts the linear translation

caused by one step of the motor from that axis (i.e. if the x-axis step motor is stepped ten times in the

positive direction, the virtual position monitor will have the x-coordinate stored as Xo+10Δx, where Xo is

the position before stepping and Δx is the linear translation of one step). Although a closed loop

Receive Datacommand byte

1st

data byte

2nd

data byte

. . .

8th

data byte

Decode

and

Execute

UARTBuffer

Verify Byte

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 19/28

18 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

RX:1F ←System sends out handshake request byte

TX:F1 ←Send back handshake byte

RX:10 ←System sends ready to receive instructions indication byte

monitoring system is not implemented on the current prototype, future designs may be able to

implement this ability to improve accuracy; See Section 6.3 for more details about planned

improvements.

The only active position monitoring system implemented is the photointerrupter sensors located at the

origin of each axis. These are actively monitored during motion of the dispenser to reset the virtual

dimensions to zero if the dispenser moves to the extent of that axis, and can be used to zero the actual

position to a reference location.

DATA GENERATION (EXTERNAL DEVICE)

Line dispense sequences are generated using ACE Converter software to generate G-code from a

Drawing Exchange Format (.dxf) file produced using AutoCAD software. The CAD (.dxf) may contain arcs

or lines only. To generate the inputs passed to the microcontroller via serial communications a custom

software package (GCODEtoHEX.exe) is used to produce the command and data bytes in the correct

sequence. The dispenser commands will be generated in the order drawn in the CAD software; this can

be used to optimize the dispensing process.Point dispense sequences can be generated by modifying the line dispense output to change the

command from line dispense to point dispense at the start of end points of a line. An example of this is

covered in Section 4.3.

4.2 COMMUNICATIONS SPECIFICATIONS

Communication between the external device and the system handled via the microcontroller’s Universal

Asynchronous Receiver Transmitter (UART) module. Transmission of 8-bit instruction bytes to the micro

controller directs the dispenser’s next movement.

Communications for the prototype are handled by the PICkit2 programmer/debug hardware and thePICkit2 UART Tool software. The user can input pre-generated code or control the dispenser in real time.

See Section 4.3 for a more detailed explanation of using software.

The system will remain idle until an appropriate command is issued via the communications. Upon

startup the system will require a handshake byte to be sent to test communication before it will receive

commands.

Upon receiving the handshake byte the system will return a byte to indicate that it is able to receive a

command byte. See the table below for available bytes to send to the system.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 20/28

19 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

RX:10 ←System sends ready to receive instructions indication byte

TX:E0 ←Command sent to system: return to origin

RX:F0 ←System sends confirmation; command is being executed

Command Command Byte Required Data bytes

Handshake byte F1 ― ―

Send dispenser to origin E0 ― ―

Run pump (for priming) E3 ― ―

Set Z-axis heightE1

Data byte 1 Z-axis height; integer value

Data byte 2 Z-axis height; decimal valuePoint dispense

EF

Data Byte 1 X-coordinate; integer value

Data Byte 2 X-coordinate; decimal value

Data byte 3 Y-coordinate; integer value

Data byte 4 Y-coordinate; decimal value

Line dispense

E8

Data Byte 1 Start line X-coordinate; integer value

Data Byte 2 Start line X-coordinate; decimal value

Data byte 3 Start line Y-coordinate; integer value

Data byte 4 Start line Y-coordinate; decimal value

Data Byte 5 End of line X-coordinate; integer value

Data Byte 6 End of line X-coordinate; decimal value

Data byte 7 End of line Y-coordinate; integer valueData byte 8 End of line Y-coordinate; decimal value

Upon receiving a verified command byte, the system will prompt the user for additional data bytes and

once it receives all necessary information will confirm that the command will be executed with a

confirmation byte.

See the below list for all prompts and confirmation outputs from the system.

Prompt/ Confirmation System Output Description

Request for handshake byteF1

System has just started up. Communications must

be initialized with the handshake byte [F1]

Ready to receive command byte10

System has completed the previous command and

is now idle until next command is issued

Request for data byte 1 01 The system requires additional information to

execute the issued command. Data bytes must be

entered in the correct order; see the previous page

for data byte ordering information.

Request for data byte 2 02

Request for data byte 3 03

Request for data byte 4 04

Request for data byte 5 05

Request for data byte 6 06

Request for data byte 7 07

Request for data byte 8 08

Execute confirmation

F0

The system has received all necessary information

to execute a command. Communications are turned

off and the command is not being executed.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 21/28

20 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

No communication can be sent while the system is executing a command. Ensure that the system

prompts for a command before transmitting any bytes.

COMMAND AND DATA BYTE STRUCTURES

Encoding of the commands bytes is done so that leading bits will allow the microcontroller to identify

the incoming data as a command byte, and the trailing bit as an integer or decimal value data byte.

The structure of the above data bytes allows the system to identify incoming data to ensure it is entered

in the correct order to ensure proper execution. While expecting a command byte, the system will check

the first four bits to ensure they match the above value. The command ID will then be checked to

determine subsequent steps.

The data bytes contain an absolute dimension in the first seven bits, for an integer value this value is in

inches and for a decimal value the number is in hundredths of an inch. It can be seen that the value will

never exceed 112 (0b1110000) and thus a data will never be interpreted as a command byte. The

trailing bit in the data byte is an ID for the program to ensure the byte is an integer or decimal value (1:

integer; 0: decimal).

4.3 EXECUTION OF SAMPLE PROGRAM

All files and conversion software in the following section are included with the dispenser CD.

Explanation of the interface to the control system is shown here by going through the steps to input a

CAD generated path to the system. Shown below is the dispense pattern (left) along with the CAD

generated file (right).

Figure 4.3-A:

Dispensing

pattern

Command byte (0xEF: point dispense)

1 1 1 0 1 1 1 1

Identity bits Command ID

Data byte (0x05: integer value 2)

0 0 0 0 0 1 0 1

Data value Integer bit

0 1 1 0 0 1 0 0

Data byte(0x64: decimal value 0.50)

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 22/28

21 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

Conversion of the CAD file (demo.dxf) is first shown here. Opening the file with ACE converter software:

Ensure that Layer 0 is turned off by double clicking the layer and checking the ‘Turn Layer Off’ option.

Ensure the arc direction for the ‘PATH’ layer is set to clockwise and cut depth is set to zero. Ensure all

settings are set as shown below by double clicking the PATH layer.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 23/28

22 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

To convert to G-code, click the convert button and ensure no options are checked in the shown dialog

box.

Now that a numerical code file (.nc) has been created, this file needs to be converted to input to pass to

the dispenser. Rename the above generated file “input.nc” and ensure that it is placed in the same

folder as the GCODEtoHEX.exe conversion software. Run the software and a file (HEXOUT.txt) will be

created containing the encoded instructions.

As can be seen in the CAD drawing, point dispense locations are generated by drawing a line from the

dispense point to the origin. To ensure the dispenser reads this input as point dispense locations the

input code needs to be modified. These lines were drawn in the CAD software last, and will be the last

three lines in the output file. Make the following changes to change from line to point dispense:

-- LINE 21 --

E8 07 FE 07 FE FF FE FF FE

-- LINE 22 --

E8 07 FE 09 FE FF FE FF FE

-- LINE 23 --

E8 05 FE 07 FE FF FE FF FE

-- LINE 21 --

EF 07 FE 07 FE

-- LINE 22 --

EF 07 FE 09 FE

-- LINE 23 --

EF 05 FE 07 FE

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 24/28

23 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

The above modification changes the command byte from line dispense to point dispense and strips the

unnecessary data bytes (end of line coordinates). See section 4.2 for command and data byte

references.

The output code can now be passed to the dispenser using the PICkit2 UART Tool software. This is

accessed by starting the PICkit2 software and selecting Tools>UART Tool. Ensure that the PICkit2

programmer is connected to the UART port (see Figure 3.1-A) and the dispenser is powered on.

Set the baud rate to 9600 in the top left corner and press ‘Connect’. The dispenser is now ready to

receive data. Enter the commands by copy and pasting each line from the HEXOUT.txt file and sending.

Analysis of the first line from (0.5, 0.5) to (2.0, 2.0) shows the command structure

E8 Command byte Line dispense

FF Data byte 1 Line start x-coordinate; integer part, value 064 Data byte 2 Line start x-coordinate; decimal part, value 0.50FF Data byte 3 Line start y-coordinate; integer part, value 064 Data byte 4 Line start y-coordinate; decimal part, value 0.5005 Data byte 5 Line end x-coordinate; integer part, value 2FE Data byte 6 Line end x-coordinate; decimal part, value 0.0005 Data byte 7 Line end y-coordinate; integer part, value 2FE Data byte 8 Line end y-coordinate; decimal part, value 0.00

Handshake byte (F1) has been sent; system prompts for a command byte

Dispenser is commanded to return to origin; acknowledges command

Command byte is sent; system prompts for first data byte

Data bytes can be sent in a stream for each

command

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 25/28

24 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

5| PROTOTYPE TESTING AND FUNCTIONALITY

MECHANICAL STRUCTURE

The layout of the structure was found to meet its design goals, but new issues were found during

construction and testing. The overhead operating mechanism was successful in allowing for a stationary

work area that has no weight restrictions and allows for use with customized workbench fixtures. Use of

aluminum as a building material resulted in easy machining of the components, and proved a strong

enough to not introduce any concerns about failure of components.

As most of the components were custom fabricated from raw materials for this design, issues with such

as alignment of the movement mechanism and other issues rising from poor dimensioning of machined

components were common. Although mechanisms could still function with these inaccuracies in

dimensioning, additional resistance and some mechanical backlash was added to the movement

mechanism.

MOVEMENT MECHANISM

The lead screw translation system powered by stepper motors was able to be implemented with some

anticipated problems. When the mechanisms were disconnected from each other the lead screws on

the x and y axis where able to be driven at close to the intended top speed without failing to step;

however when connected together the rail-roller system made proved to be poorly designed and

misaligned. At certain sections the resistance from rolling friction and a bending force on the lead screw

caused the stepping motors to misstep and good accuracy could not be attained. After loosening the

system by using split washers for increased spacing between components, the system lost rigidity but

did not get stuck while moving. The shake in the system was determined to affect the accuracy of the

output, line dispense paths can show the position error problems as the dispenser nozzle can be seen to

deviate from its straight line path. Alignment issues in the vertical axis mechanism reduced the actual

vertical displacement of the cart to 1.25”. This problem could not be solved.

The lead screw mechanism proved to be mechanically accurate. The system was able to be used to

provide accurate dimensional output from calculations established in the design stage of the system. No

compensation for inaccuracies was required in the software. The system did show weaknesses in

repeatability, a maximum of 0.22” deviation from the intended position after 37” of movement was

measured. Based on usability of this prototype, the dimensions of the work area can be easily modified

to larger sizes by simply extending the size of the lead screw and railings to the desired length in the

subsequent design. The modularity of this design is a large success.

STEP MOTOR OPERATION

Control of the step motors through the L297 based control circuit proved successful. Motors where able

to be driven accurately with no calibration needed and no noticeable discrepancies between stepping

speeds and calculated output pulse frequency could be seen.

Issues occurred when motors were connected to the lead screws and the mechanism resistance was

larger than accounted for. The motors frequently missed steps and would not turn when faced with

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 26/28

25 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

some resistance. Based on the motor torque curves, motors were estimated to be able to run at 60

RPM; however the unaccounted additional mechanical resistance resulted in a reduction in speed to

22.5 RPM. Testing proved that at this speed the motors could be operated with confidence that the

motors would not misstep at significant frequencies. Hold torques on all motors were sufficient, while

powered on and stationary, the mechanism could not be moved by outside interference.

PUMPING SYSTEM

After evaluation of the pumping system, it has been concluded that the pump chosen may not be the

best method of fluid displacement. The advantages of the peristaltic mechanism, especially the

versatility in fluids able to be pumped, was noticed and appreciated immediately. The design of this type

of pump, however, provides pulsating fluid flow rate. This proved to not be a problem for point

dispensing, however dispensing of linear paths proved problematic. A pump encoder feedback, along

with PWM motor speed control was proposed to provide a more continuous pump motion, but this

system was not implemented on the current prototype.

MICROCONTROLLER

The 8-bit microcontroller was found to be the bare minimum to implement this sort of system. Limited

program and data memory limited the complexity of the system to merely a motor control system with

minimal feedback. Without expanded flash and program memory, the microcontroller unit (MCU) could

not execute more demanding calculations involving large floating point math and the accuracy of

received commands was kept to 0.01”. Implementation of advanced functionality, such as PID control of

positioning and advanced arc and spline path motions, require a more powerful MCU or two or more

MCUs in parallel to handle motor control and position monitoring simultaneously.

USER INTERFACE

A graphic user interface was under development that would handle all of the communication with the

machine, allowing a user to leave the machine running unsupervised. Communication issues with the

original hardware intended to be used resulted in switching to using the PICkit2 tool to handle

communications. With this hardware, the intended software could not be used and the user had to

enter command data manually.

Implementation of CAD programs for path design proved successful. Improvements need to be made to

allow a more intuitive conversion process.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 27/28

26 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

6| FUTURE DEVELOPMENT

6.1 CHANGES TO MECHANICAL SYSTEM

To remove inaccuracies from machining custom components a simpler design is proposed. Although

more costly, a pre-manufactured precision bearing railing system or vice rail has been determined to benecessary to alleviate the mechanical instability that is limiting the current system.

Using railings will allow for an increase in speeds but for most fluid dispensing applications it has been

determined that the mechanical accuracy of the current systems is unnecessarily small and speed is

more important. This means step motors with a less accurate resolution but higher speeds and higher

torques can be used.

Although the pumping system proved inadequate for line dispensing on the current prototype, the

solution to this problems has been determined to be an improved control system on the pump motor

rather that switching to another dispensing system.

6.2 CHANGES TO ELECTRICAL SYSTEM

The current electronics proved to be very reliable and no significant changes are felt necessary. The

changes to be made are modification of the control circuitry into a package closer to the final product.

Circuit components can be included on one more compact circuit board. Use of advanced PCB

manufacturing technology will allow the use of more surface mount ICs and electronic components

which will reduce the size of the boards. A hardware change to a more permanent communication

system from the current PICkit2 tool is necessary for user convenience. A working UART to USB

connection will be implemented on the next model.

An important addition to the electrical system would be the addition of an optical encoder system to the

lead screws. This would allow precise monitoring of the real position of the cart and allow the system to

detect and fix any missed steps. These sensors would need an angular resolution at least as small as the

stepper resolution to detect missed steps.

6.3 CHANGES TO CONTROL SYSTEM

Testing revealed that possible replacements of the microcontroller unit (MCU) would be a more

powerful 16-bit micro controller or to split the necessary output and handling of data to two 8-bit MCUs

operating in parallel. Both systems would require external data memory to act as a communication

buffer for the two units. This would allow simultaneous communication and operation as well asposition control using external sensors and implementing PID control.

Implementation of sensors to detect rotation of the screws will allow real-time position monitoring and

provide data to compare to the virtual position. Motor speeds can be varied in real time to correct for

missed steps. This will allow for some allowance to run at higher speeds where missed steps are more

likely for mechanical reasons. These missed steps can then be corrected for used closed loop feedback.

8/7/2019 controle motor de passo microcontrolador

http://slidepdf.com/reader/full/controle-motor-de-passo-microcontrolador 28/28

27 MIE443 DISPENSING ROBOT PROTOTYPE TECHNICAL MANUAL AND DATA SHEET

This will improve the accuracy of the machine and allow the full resolution of the mechanical system to

be exploited.

An improved pump control system will likely need to be implemented to improve the accuracy of

volume dispensed. The peristaltic pump allows for this but an encoder feedback must be established to

allow for accurate dispensing of fluid, independent of fluid properties. The peristaltic pump dispenses acontestant volume per revolution, thus implementing PID control to accurately control the pump

revolutions will allow accurate dispensing and give possibility of feedback to the user of the volumes of

fluid being dispensed.

6.4 CHANGES TO PROGRAM INTERFACE

A visual user interface that allows the user to control the dispenser in real time or load and create pre-

programmed paths is under development that automates the communication and data conversion

process is under development. With additional development that will allow simultaneous motor control

and communication, the possibility of live feedback of the dispenser position to a graphic interface from

position feedback sensors exists. An easy to use user interface will allow more intuitive control of the

dispenser.