Treinamento_SNP

-

Upload

alfredo-machado-neto -

Category

Documents

-

view

219 -

download

0

Transcript of Treinamento_SNP

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 1/31

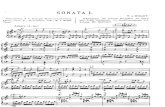

TreinamentoSAP APO

SNP – Supply Network Planning

SAP APO1

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 2/31

ÍNDICESupply Network Planning.............................................................................................................3

Purpose.....................................................................................................................................3

Features.....................................................................................................................................3

Supply Network Planning Process...............................................................................................4Purpose.....................................................................................................................................4

Process Flow.............................................................................................................................4

Planning Area Administration......................................................................................................7Purpose.....................................................................................................................................7

Prerequisites.............................................................................................................................7

Process Flow.............................................................................................................................7Master ata !or Supply Network Planning................................................................................1"

Purpose...................................................................................................................................1"

Process Flow...........................................................................................................................1"

Master ata Setup !or t#e $ptimi%er..........................................................................................13Purpose...................................................................................................................................13

Process Flow...........................................................................................................................13

&esult......................................................................................................................................17Model'(ersion )reation..............................................................................................................1*

Purpose...................................................................................................................................1*

Process Flow...........................................................................................................................1*Supply )#ain Model Set +p.......................................................................................................1,

Purpose...................................................................................................................................1,

Prerequisites...........................................................................................................................1,

Process Flow...........................................................................................................................1,&esult......................................................................................................................................"-

&elease o! t#e emand Plan to SNP.........................................................................................."1

Purpose..................................................................................................................................."1Prerequisites..........................................................................................................................."1

Supply Network Planning Met#ods............................................................................................""

+se..........................................................................................................................................""$ptimi%ation Planning............................................................................................................""

$ptimi%ation Pro!iles.............................................................................................................."7

Adanced Macros......................................................................................................................."*+se.........................................................................................................................................."*

/ntegration..............................................................................................................................."*

Prerequisites..........................................................................................................................."*

Features..................................................................................................................................."*&unning t#e $ptimi%er !rom t#e /nteractie Planning esktop.............................................",

SAP APO"

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 3/31

Supply Network Planning

Purpose

APO Supply Network Planning integrates purchasing, manufacturing, distribution, andtransportation so that comprehensive tactical planning and sourcing decisions can be simulated andimplemented on the basis of a single, global consistent model. Supply Network Planning uses advancedoptimization techniues, based on constraints and penalties, to plan product flow along the supply chain.!he result is optimal purchasing, production, and distribution decisions" reduced order fulfillment times andinventory levels" and improved customer service.

Starting from a demand plan, Supply Network Planning determines a permissible short# tomedium#term plan for fulfilling the estimated sales volumes. !his plan covers both the uantities that mustbe transported between two locations $for e%ample, distribution center to customer or production plant todistribution center&, and the uantities to be produced and procured. 'hen making a recommendation,Supply Network Planning compares all logistical activities to the available capacity.

!he Deployment function determines how and when inventory should be deployed to distributioncenters, customers, and vendor#managed inventory accounts. (t produces optimized distribution plansbased on constraints $such as transportation capacities& and business rules $such as minimum costapproach, or replenishment strategies&.

!he Transport Load Builder $!)*& function ma%imizes transport capacities by optimizing loadbuilding.

(n addition, the seamless integration with APO +emand Planning supports an efficient SOPprocess.

Features

Supply Network Planning is used to calculate uantities to be delivered to a location in order tomatch customer demand and maintain the desired service level. Supply Network Planning includes bothheuristics and mathematical optimization methods to ensure that demand is covered and transportation,production, and warehousing resources are operating within the specified capacities.

!he interactive planning desktop makes it possible to visualize and interactively modify planningfigures. -ou can present all key indicators graphically. !he system processes any changes directly vialiveache.

SAP APO3

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 4/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 5/31

arry out all the steps needed to set up your planning area. !he planning area is the basis for allactivities in APO Supply Network Planning. (t is a collection of parameters that define the scope of all planning tasks.

• APO !aster Data Setup

Supply Network Planning is a very master data#intensive component of APO. 'hether you plan to

use the 1euristic, Optimizer, or apable#!o#2atch $!2&, the master data must be set up withcare to achieve the desired results. 2aster data for Supply Network Planning includes locations,products, resources, and production process models $PP2s&.

• !oel"#ersion Creation

-ou must create a model name before you set up the model in the Supply hain 3ngineer $S3&and assign the model to at least one version. -ou can assign the model to several differentversions for simulative purposes. !he version is also used for the release of the +emand Plan$final forecast& to Supply Network Planning, and vice#versa.

• Supply C$ain !oel Setup

-ou set up the supply chain model for Supply Network Planning in the Supply hain 3ngineer$S3&. (n the S3, you assign the locations, products, resources, and PP2s to a model. -ou then

add transportation lanes to link supply to demand locations, allocate products to the transportationlanes, and maintain uota arrangements.

• %elease Deman Plan to SNP

-ou release the demand plan from +emand Planning to Supply Network Planning. !he demandplan is often unconstrained by any production or distribution restrictions. !his step can be carriedout by either the demand planner the SNP planner.

• Supply Network Planning !et$o Determination an Pro&ile Settings

-ou determine which of the following methods to use for your planning4 optimization, heuristicplanning, supply demand propagation, apable#!o#2atch planning, and5or safety stockplanning. !hen you make the settings in the appropriate profiles for each of the methods for which

this is reuired. !hese profiles can be changed on the fly for simulation purposes. !hey can alsobe used to perform mass maintenance of product master data. -ou may need enter additionalmaster data specifically for the method that you are using.

• Supply Network Planning %un

-ou e%ecute planning based on the methods you chose, including all prereuisite stepsPerforming the supply network planning run using the 1euristic, Optimizer, Supply +emand

Propagation, or apable#!o#2atch results in a mid#term production and distribution plan.

• Interacti'e Planning

After the Supply Network Planning run, you review the plan in the interactive planning desktop. (f you use, for e%ample, the 1euristic planning method, you can also level resource capacity toresolve problems from the interactive planning table.

• %elease o& Supply Network Plan to Deman Planning

SAP APO0

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 6/31

-ou release the f inal supply network plan back to +P for comparison of the unconstrained demandplan to the constrained supply network plan. 2a6or discrepancies between these two plans couldtrigger re#forecasting, and, ultimately, re#planning. 7or e%ample, you may release the supplynetwork plan back to +P if the capacity situation cannot cover demand created by a promotion, soyou must make changes in the promotional planning strategy in +P.

• Con'ersion o& SNP Orers into PP"DS Orers

!his is not part of part of the Supply Network Planning process since it can only bee%ecuted in Production Planning and +etailed Scheduling $PP5+S&. 1owever, it isincluded in the cycle because this step is usually performed before running +eploymentand !ransport )oad *uilding.

(n PP5+S, you convert supply network planning orders into PP5+S orders to make them availablefor production planning and detailed scheduling.

• PP"DS Planning

!his is not part of the Supply Network Planning process because it can only be e%ecuted

in PP5+S. 1owever, it is included in the cycle because production planning and detailedscheduling is usually performed before running +eployment and !ransport )oad *uilding,which are included in the Supply Network Planning interface.

(n PP5+S, you create a viable production plan based on the planned orders generated in SupplyNetwork Planning.

• Deployment %un

After production planning is complete and the system knows what will actually be produced $thisinformation is stored automatically in liveache&, the +eployment run generates confirmedtransport orders.

• Transport (oa )uiling

!he !ransport )oad *uilding $!)*& run groups the confirmed transport orders resulting from the+eployment run into transportation plans. 7or transport orders that could not be satisfied duringthe !)* run due to specified constraints, you can build transportation plans manually.

SAP APO

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 7/31

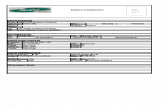

Planning Area Aministration

Purpose

Setting up the environment for Supply Network Planning is essential to successfully carry outplanning. Planning area administration is the first step in this setting#up process.

Planning area administration is similar for both Supply Network Planning and +emandPlanning. 7or that reason, the process below covers most of the steps involved for bothapplications.

Prere*uisites

-ou have understood the differences between the different storage methods in Supply Network

Planning and +emand Planning, and know which functions are supported by which storage methods. 7or more information, see +ata Storage in Supply Network Planning and +emand Planning.

-ou have understood the role and purpose of the following4

• 8ey 7igure

• haracteristic

• Attribute

• 2aster Planning Ob6ect Structure

• Aggregate $used in +emand Planning only&

• Storage *uckets Profile

• Planning Area • Planning *ook

Process Flow9. +ecide which key figures you want to store in (nfoubes and which key figures you want to save

in liveache. !ypically you store actual data for +emand Planning in an (nfoube, along with oldplanning data" and you save current planning data for +emand Planning in liveache time seriesob6ects. 8ey figures are also stored in time series ob6ects in Sales Operations Planning.

-ou will need a key figure for each department and5or business partner that will create a forecast.

7or each key figure that you intend to forecast $for e%ample, demand uantity&, decide whether you will also need key figures for corrected history, corrected forecast, promotions, e%#postforecast, and5or e%#post 2): forecast.

+ecide whether you need key figures in which to store forecasts from previous periods and5or uarterly or other cumulative subtotals.

SAP APO7

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 8/31

7or any key figure whose fi%ed values you wish to save, you will need a second key figure inwhich the fi%ed values will be stored.

+o not include " spare " key figures. (f you later decide that you need an e%tra key figure, you canadd it then.

;. (f the key figures that you want to use for planning do not already e%ist in the system, create themby choosing Tools → Edit nfo O!"e#ts in the Administrator 'orkbench.

Standard SNP key figures come predefined with APO. -ou do not have to create them.

(f the system asks you to choose between an APO key figure and a *' key figure, choose APOkey figure. !his allows you to use the APO functions for key figures such as fi%ing.

'hen creating a key figure for monetary values, select the type Amount$ choose the data type/:: and enter the unit5currency <S!A!=/:: or <urrency. 7or uantities, select %uantity$

choose the data type >/AN and enter the unit <*AS3=/O2 or </nit.

(f you wish to be able to fi% $that is, lock& the values of a key figure in interactive planning, both thekey figure to be fi%ed and a key figure in which the fi%ed values are stored need to e%ist in thesystem. 7irst create the key figure in which the fi%ed values should be stored. !hen create the keyfigure you want to fi% and in the field 7i%ed key figure attach the storage key figure. -ou find thisfield on the tabstrip !ype5unit.

?. +ecide which characteristics you want to use as planning levels and which characteristics youwant to use only for selection and navigation. !o find out what the difference is between these twotypes of characteristic, see Attribute.

@. (n the Administrator 'orkbench, check to see if these characteristics already e%ist in the system.7or e%ample, the standard APO system comes with the characteristic A2A!N: for product and

A)ONO for location.

(f you cannot see these standard characteristics, run program 5sapapo5ts=d=ob6ects=copy tocreate them in your system.

See also the information on the integration between Supply Network Planning and +emandPlanning in +ata Storage in Supply Network Planning and +emand Planning.

(f the characteristics delivered with the system are not sufficient for your needs, create them bychoosing Tools → Edit nfo O!"e#ts in the Administrator 'orkbench.

a. reate the characteristics you want to use as planning levels.b. reate characteristics that will be used for selection and navigation, but not as planning

levels.B. Assign na'igational attri+utes to the characteristics you want to use as planning levels. 7or

more information, see Attribute.

SAP APO*

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 9/31

C. (f you want to store different versions of the same key figure in different places, see +ata Storagein Supply Network Planning and +emand Planning.

D. reate storage +ucket pro&iles by choosing Periodi#ities for Planning Area from the currentsettings for Supply Network Planning and +emand Planning. 7or more information, see Storage*uckets Profile.

E. reate planning +ucket pro&iles by choosing Define planning !u#ket profiles from ustomizingfor Supply Network Planning and +emand Planning. 7or more information, see Planning *ucketsProfile.

. reate the APO 'ersions that you want to use for Supply Network Planning and +emandPlanning, and assign these versions to a supply chain model.

!his step may also be come earlier in the administration process.

!he concept of versions is different than in previous releases. (n :elease ;.<A there were twokinds of versions4 demand planning versions, which were saved in (nfoubes, and APO versions,which were assigned to models and saved in liveache. As of :elease ?.<A there is only one kindof version4 the APO version. !he APO version is used in all applications including +emandPlanning.

+ata in Supply Network Planning and +emand Planning is now divided up according to planningarea, a further subdivison of which is the version. onseuently, the data you save to APO version9 in planning area 9 does not overwrite the data in APO version 9 in planning area ;.

7or information on how to store the same key figure in multiple versions, see +ata Storage inSupply Network Planning and +emand Planning.

9<. reate and activate a master planning o+,ect structure- Supply Network Planning comes withthe standard master planning ob6ect structure &ASNPBAS. -ou can, however, create your own.Start by choosing Administration of Demand Planning and Supply Network Planning from theSupply Network Planning or +emand Planning current settings, choosing Planning o!"e#t stru#tures from the pull#down menu on the top left, right mouse clicking the Planning o!"e#t stru#tures folder and choosing 'reate master planning o!"e#t stru#ture(

(nclude only the characteristics that you intend to use as planning levels. 7or Supply NetworkPlanning, select SNP)relevant . !he following characteristics are automatically included in themaster planning ob6ect structure4

A2A!N: product

A)ONO location

A:NA23 resource

APP2NA23 production process model $PP2&

A!:NA23 transportation lane

AA!NA23 activity

SAP APO,

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 10/31

(f you use to use your own characteristics in addition to ones listed above, you can createhierarchical characterisitcs.

7or more information, see 2aster Planning Ob6ect Structure and (2F.

99. 7or +emand Planning only, create the aggregates in which you wish to save data by right mouse

clicking the master planning ob6ect structure and choosing 'reate aggregate. 7or a definition of an APO aggregate, see Aggregate.

9;. reate a planning area by choosing Administration of Demand Planning and Supply Network Planning from the Supply Network Planning or +emand Planning current settings and choosingPlanning area from the pull#down menu on the top left. 7or more information, see Planning Areaand (2F.

9?. Set up your master data for Supply Network Planning and +emand Planning.9@. (nitialize the planning area by right mouse clicking the planning area and choosing 'reate time

series o!"e#ts.

(f you need to re#initialize a planning area after an update to your master data or in order to e%tendthe planning horizon, you do not need to delete the old time series ob6ects before you can createnew ones. !he system recognizes where new characteristic value combinations or new time

series e%ist, and creates time series ob6ects only for the new master data.

-ou delete the time series ob6ects if, for e%ample, you have five versions and you only need tokeep two of them.

9B. reate planning books and planning views. -ou can assign the planning books and planningviews to individual users. SAP provides standard planning book views for use in the following4

Deman Planning4 to do forecasting using any forecast strategy, multiple linear regression, or composite forecasting.Supply Network Planning4 to do Sales Operations Planning, +istribution :esource Planning,!ransport )oad *uilding, or Gendor#2anaged (nventory.

(n Supply Network Planning, depending on what type of planning you wish to conduct,the following standard planning books and data views are provided.

Interactive Supply Network Planning (n interactive Supply Network Planning $from the SAP 3asy Access 2enu, choose Supply

Network Planning → Planning → ntera#tive Supply Network Planning &, you see thestandard planning book SNP94 with the views SNP94(1) - SNP Plan and SNP94(2) - Capacity Check in the data views area. !he planning book SNP&* offers you thefunctionality that was available for Supply Network Planning in :elease ;.<A. !he onlyma6or difference is that you now access the !ransport )oad *uilder through theapplication toolbar. Note also that you fi% values differently than in +emand Planning. -oufi% orders, not cells. 7i%ed orders are not overwritten by the ne%t SNP run. 7or more

information on the planning book SNP94, see +ata Storage in Supply Network Planningand +emand Planning.

Sales !perations Planning (S!P)(n Sales Operations Planning $from the SAP 3asy Access 2enu, choose Supply

Network Planning → Planning → Sales + Operations Planning ,SOP--, you see the

standard planning book 9"S!P with the views S!P(1) # S!P $ocation Pro%ucts,S!P(2) # $anes, S!P(&) # S!P PP' , and S!P(4) # S!P esource in the data viewsarea. !he book allows you to do sales planning, production planning, and mid#term

SAP APO1-

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 11/31

capacity leveling on one screen. 7or more information on the planning book 9"S!P , see+ata Storage in Supply Network Planning and +emand Planning.

istri*ution esource Planning (P)(n +istribution :esource Planning $from the SAP 3asy Access 2enu, choose Supply

Network Planning → Planning → Distri!ution .esour#e Planning ,D.P--, you see the

standard planning book 9"P with the views P1 - P in the data views area. !hisinterface is practically identical with interactive Supply Network Planning, however hereyou can also view the distribution receipts and distribution issues.

+ransport $oa% ,uil%ing (+$,)(n the standard planning book SNP94, the !ransport )oad *uilder $from the SAP 3asy

Access 2enu, choose Supply Network Planning → Planning → Transport Load Builder

,TLB$ or choose on the ntera#tive Supply Network Planning screen - offersall of the functions that were available in :elease ;.<A. Now, however, you find all of thefunctions on the same screen. -ou access some of the functions by clicking the rightmouse button on the headings in the table. 2oreover, you can make manual modificationsto the !)* results by dragging and dropping the recommendations5orders in the table.

Interactive 'I (n (nteractive G2( $from the SAP 3asy Access 2enu, choose Supply Network Planning →

Planning → /0 → ntera#tive /0-, you see the standard planning book 9"'I with theview 9"'I(1) - 'I in the data views area. (n addition to the typical SNP data that youcan display, you also can display the values for your G2( receipts and demands $planned,confirmed, and !)*#confirmed&.

SAP recommends that you use the standard planning books to do Supply NetworkPlanning, creating additional planning books, if necessary, using the standard ones astemplates.

SAP APO11

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 12/31

!aster Data &or Supply Network Planning

Purpose

2aster data is the essential data, such as information concerning products, locations, resources,production process models, and so on, reuired to build a supply chain model and e%ecute planning.

(n addition to the general master data mentioned above, each of the Supply Network Planningmethods reuires particular master data. 7or e%ample, to e%ecute Advanced Safety Stock Planning, youmust enter specific data $for e%ample, safety stock, safety stock method, service level, and so on& on theLot si1e tab in the product master. !he information regarding the individual master data fields supportedfor each method by Supply Network Planning are listed below.

Process Flow9. -ou create the general master data for your location products.;. -ou decide which method to use in Supply Network Planning and create the master data

specifically for it.

See also.2aster +ata Setup for Safety Stock Planning2aster +ata Setup for the Optimizer 2aster +ata Setup for the 1euristic 2aster +ata Setup for Supply +emand Propagation2aster +ata Setup for apable#!o#2atch2aster +ata Setup for +eployment2aster +ata Setup for the +eployment Optimizer 2aster +ata Setup for the !ransport )oad *uilder

SAP APO1"

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 13/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 14/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 15/31

<;, the capacity check will trigger an alert if resource consumption e%ceeds the normalcapacity defined in active variant <9.

• :eference resource

Planning Parameters ta+• Activity overlaps periodsH # -ou must activate this flag only if the model includes PP2 activities or

transportation times that last longer than one day.• +ay #5+ay J # !he resource capacity0s validity period

• Not relevant for SNP

• apacity overload $K&

• 2in. utilization of capacity $K&

)ucket ta+• *ucket capacity # if the planning period for the Optimization run falls outside the time interval

defined in the #apa#ity variant • /nitH # /nit of measure for 'apa#ity $the unit for a production resource is usually time, but the unit

for a storage resource is volume or weight, for e%ample&. !his field is reuired so the Optimizercan convert units of measure defined throughout the system appropriately.

•

Number of periods• Period types

Capacity variants # +efine two capacity variants4 one variant for standard capacity, another forma%imum capacity $the ma%imum capacity variant should be specified as the A#tive variant on the5eneral data tab&.E8ample. Normal machine capacity is E hours" ma%imum capacity is 9< hours. !he Optimizerdoes not associate any costs with the use of normal capacity" however, if the ma%imum capacity isconsidered by the Optimizer during the calculations, the Optimizer applies the cost penalty forincreased use of a production resource defined in the 'ost profile.

• hoose *ucket resource or Single mi%ed resource tab

• Galid fromH

• Galid toH

• >uantity5rate definitionH

De&initions 1*uantity"rate3• >uantity5rate definition $name&H

• Galid toH

• PlannerH

• Number of periodsH

• Period typeH

• *ucket capacityH

• /nit of measureH

• ost

9- Assign resources to locations in location master ata

:- Create PP!s

• Plan numberH

• /sage4 S $for SNP&H

!perations

SAP APO10

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 16/31

• +escription of PP2

• Single level costs

• 2ulti level costs

• ost function $cost profile&

• OperationH

• +escription $of operation&

"ctivity

(n Supply Network Planning, each activity must cover at least a day, or more than oneday. 3ach operation can also contain only one activity.

• Activity numberH

• +escription $of activity&

• Activity type

• Scrap K

Co.ponents ta*

• ProductH

• (nput5output indicatorH

• onsumption typeH

• +ate fromH

• +ate toH

• /nit of measure

'o%es ta*

• 2odeH

• Primary resourceH $reuired only if resources are connected to this PP2&

• )ocationH $reuired only if resources are connected to this PP2&

• /nit of measure $must be Day &H

• 7i%ed durationH

esources

• :esource

• )ocation

• *ucket consumption

"ctivity relationships - Pre%ecessor/successor ta*s

• Operation name

• Activity number

Pro%uct plan assign.ent *utton

• PP2 and descriptionH• Galidity $date5time&

• )ocationH

• +iscretization

• *ucket offset

• 2inimum and ma%imum lot sizesH

SAP APO1

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 17/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 18/31

!oel"#ersion Creation

Purpose

(n this process, you create a model name and assign the model to a planning version so that youcan you can model the supply chain in the Supply hain 3ngineer in the ne%t step. -ou must define themodel name before you can set up the supply chain model.

reating multiple versions of the model allows you to perform simulative planning and what)if scenarios without corrupting the supply chain model.

Only the active version receives data from :5? via (7.

Process Flow

9. reate a model name and give it a description.;. Assign the model to at least one planning version

• Planning version name and description

• SNP4 hange planning active $set flag to active&

• PP5+S4 hange planning active $set flag to active&

(f you use PP5+S, you must set the PP6DS7 'hange planning a#tive and SNP7 'hange planning a#tive indicators to enable automatic planning to be triggered or planning fileentries to be created when changes relevant to planning occur. !hese indicators areimportant when converting Supply Network Planning orders into PP5+S orders and vice#

versa. -ou must set these indicators for the target planning version" otherwise you willhave to plan all orders manually.

SAP APO1*

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 19/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 20/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 21/31

%elease o& t$e Deman Plan to SNP

Purpose

!his process makes the demand plan available to the supply chain planner if the supply chainplanner does Supply Network Planning using liveache orders. !he supply chain planner can then usethe demand plan as a basis for making sourcing, deployment and transportation decisions. 7rom atechnical point of view, you are copying data from liveache time series ob6ects to a forecast category inthe liveache orders.

(f Supply Network Planning is done in liveache time series, see opy 2anagement.

(n a separate process the supply chain planner releases the SNP plan to +emand Planning. 'henyou do this, data of particular categories in the SNP plan, which has been created or changed by thesupply chain planner, is copied to a predefined key figure in a +P planning book. 1ere, you can doreporting on the released data and, in particular, compare the original MunconstrainedM demand plan withthe MconstrainedM SNP plan. 7or more information, see :elease of Supply Network Plan to +emandPlanning.

Prere*uisites• -ou have created product master records for your products.

• -ou have created location master records for your locations.

• -ou have set up your supply chain models.

• (f applicable, you have defined the location split for the release to Supply Network Planning. 7ormore information, see )ocation Split.

• (f applicable, you have defined a product split. 7or more information, see Product Split.

SAP APO"1

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 22/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 23/31

!he optimizer uses linear programming to consider all planning problem#relevant factorssimultaneously in one optimum solution. As more constraints are activated, the optimization problembecomes more comple% and, as a general rule, the time reuired to solve this problem increases.Optimization should generally be e%ecuted as a batch activity.

!he Optimizer differentiates between #ontinuous and dis#rete linear optimization problems.

Continuous Optimi/ation!here are three methods for solving continuous linear optimization problems with the Optimizer4• Primal Simple% 2ethod

• +ual Simple% 2ethod

• (nterior Point 2ethod

All three methods arrive at an optimal solution. !he main difference in the application of thesemethods may be the runtime. !here is no general rule known for selecting the best method for a givenproblem $e%cept testing each one of them&. A good measure for the application is benchmarking on a testscenario because the optimal choice of the method depends mainly on the structure of the supply chainand less on the given input data. !herefore, in a productive environment, daily benchmarking is notnecessary.

Discrete Optimi/ation A problem is not continuous $that is, discrete& in Supply Network Planning, when the model contains4• +iscrete lot sizes for PP2s $in integers&

• +iscrete means of transport

• +iscrete capacities for transportation or production

• 2inimum lot sizes for transportation or PP2s

• Piecewise linear cost functions for transportation, production, or procurement

• 7i%ed PP2 resource consumption

(f the optimizer is to include one of these named restrictions, you must use a discrete optimizationmethod that can be selected in the SNP optimizer profile. +iscretization can be performed in two ways4 fullsearch or partial search.

!he full search uses *ranchut techniues. !o avoid e%cessively long runtimes, you should limit thenumber of improvement steps and5or the runtime $in minutes& the Optimizer is allowed to use. Animprovement step means that the system moves from one valid solution to the ne%t improved validsolution. (f you enter a search value in the appropriate field in the SNP Optimizer profile, the systemchecks both criteria simultaneously. (f you make no entry, it results in an unlimited runtime, which meansan unlimited number of improvement steps are allowed.

!he partial search algorithm solves rela%ations of the original problem seuentially to determinevalues for the discrete variables. A rela%ation means that the discretization constraint is not taken intoaccount. 7or the rela%ed problem, the )P solver $the linear programming solution process& generates anoptimal solution but with some decision variables violating their discreteness constraint. !hese violationsare solved incrementally by fi%ing the decision variables to neighboring discrete values.

7or e%ample, a decision variable with value @.D in the rela%ed optimal solution may be fi%ed either to @or B. All these decisions generate a binary decision tree with depth eual to the number of given discrete

decision variables. !his decision tree is therefore e%ponential in size, and can not be evaluatedcompletely. (nstead of this, only the most promising branches are evaluated in some sophisticated depthfirst strategy. 'ith the Preferred rounding thresholds you are able to partially control this search viapreferences. Non#discrete values for minimal lot sizes below the rounding threshold are rounded downfirst.

:ounding limit of <.@, minimum lot size of ;<<4 7or a decision variable with values smaller than E<, first try uantity <, then try uantity ;<< as a second choice. (n order to achieve a

SAP APO"3

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 24/31

good service level you could choose a production rounding limit of <.<. *y doing this youare telling the system to produce at least as much as the rela%ed optimal solutionproposes. :emember, these discretizations are done incrementally4 (f the rela%ed solutionproposes production of a uantity with a minimum lot size of <.9 every day, this does notmean that the discretization with a rounding limit of <.< tries to produce a uantity of 9minimum lot size every day, but instead on the first of at most ten days. A rounding limit of <. tries to produce nothing in the first nine days and finally on the tenth day, it tries toproduce 9 minimal lot size $even if the penalty for late delivery is high&.

!he pie#ewise linear #ost fun#tion that you can define in the master data, differentiates betweentwo important cases4 #onve8 #ost fun#tion $cost per unit increases for higher volumes, for e%ample,modeling over#time or night shifts& and #on#ave #ost fun#tion $cost per unit decreases for higher volumes,for e%ample, modeling freight rates&.

onve% cost functions do not complicate the planning problem and can be solved efficiently. Alternatively, they could even be modeled without using the feature of piecewise linear cost functions withalternative modes.

• 2ode 9 with LB< per unit and a limited capacity of eight models"

• 2ode ; with L9<< per unit and limited capacity of si% models

• onve% functions of labor cost per day, assuming eight normal working hours and a ma%imum of

si% hours of over#time with doubled per hour wages

(n contrast, concave piecewise linear cost functions could not be solved by an )P solver but usingdiscretization techniues $mi%ed integer linear programming&. (f piecewise linear functions are modeled,but the optimizer is run without discretization, or the discretization horizon is less than the planninghorizon, then the optimizer includes the definable linear cost function in addition to the piecewise linear cost function.

+iscretization cannot be used with strict prioritization./sing discretization can greatly increase runtime reuirements. 8eep in mind that SupplyNetwork Planning is a mid#term planning function. !herefore, solving integer problems $inother words, using discretization& should not be the focus of Supply Network Planning.

Prioriti/ation!he Optimizer can differentiate between the priority of customer orders and forecasted demand.

'ith strict prioritization, sales orders always have priority 3, the corrected demand forecast priority 9 , andthe demand forecast priority : . 'ithin each priority class all available cost information is used by thesystem to determine the final solution. 'hen cost#based prioritization is employed, the optimizer usespenalty cost information from the product master data $SNP3 tab& to determine the optimal solution.

Decomposition!he primary focus of decomposition is to reduce the runtime, and memory reuirements of

optimization. *oth Time de#omposition and Produ#t de#omposition are strategies that can be used incon6unction with continuous and discrete optimization.

+ecomposition gives the user a fle%ible tool for balancing the tradeoff between optimization uality

and reuired runtime. !ime decomposition speeds up the solution process by dividing the source probleminto a series of sub#problems. !hese sub#problems are then solved seuentially. (n general the uality of the solution is lower than when using the optimizer without time decomposition. Product decompositionspeeds up the solution process by building groups of products. !he complete model solves one productgroup at a time according to the window size selected. !he rule of thumb is as follows4 the smaller the

window size, the less time it will take to find a solution, but the larger the window size, the better theuality of the solution found.

SAP APO"4

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 25/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 26/31

• !ransportation cost

• 1andling capacity

• 1andling cost

• Production capacity

• Production cost

• Storage capacity

• Storage cost• !ime stream $location master data&

• )ot sizing $minimum, ma%imum and rounding value&

• Scrap

• Alternate resources

• +emand violation penalty costs

• Safety stock violation penalty costs

• Procurement costs

• Shelf life

• ost multipliers

• )ocation#specific products

• +emand profile

• Supply Network Planning demand profile

• Supply Network Planning supply profile

• 7i%ed PP2 resource consumption

Ot$er Consierations• !he result of the optimization run does not include pegging of final orders back to the original

individual demand because the demands are bucketed. • !he implication of not pegging final orders back to individual demand is the following4 (n Supply

Network Planning, there is no order#based planning. No information concerning links betweencertain planned production orders and original sales orders can be established after theoptimization run $or after the 1euristic run" however, !2 can provide e%actly such information viaorder tracking&.

• !he Optimizer considers all capacity and all alternative capacity that is available globally $at alllocations&.

• +epending on the system settings, the Optimizer can either provide no solution for a capacityoverload situation or increase capacity based on a penalty cost calculation.

• !he location product specific storage upper limit is time#independent and can not be e%tended forcosts.

• !he Optimizer considers all active types of capacity constraints, including transportation,production, handling, and storage constraints. 'hether a constraint is active or not depends onthe setting in the SNP Optimizer profile.

• !he Optimizer considers shelf life.

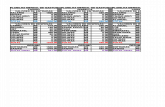

Optimi/ation Pro&iles

5se

SAP APO"

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 27/31

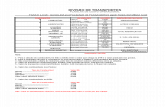

!he following table describes, in general, the profiles the Optimizer uses and how. Access eachprofile individually from the SAP APO 3asy Access menu. hoose Supply Network Planning →

Environment → 'urrent Settings → Profiles , or Profiles in Supply Network Planning ustomizing. 7or more information on these profiles, see the (mplementation Fuide $(2F&, and the field#level help for eachprofile.

Pro&ile 5se in Optimi/ation Planning %un

SNP +emand Profile (n this profile, you specify how the system calculates demand via thefore#ast hori1on $demand types& and demand hori1ons $in con6unction with#ategory groups in ustomizing&.

SNP Supply Profile (n this profile you specify how the system calculates supply via theproduction horizon and supply horizons $in con6unction with #ategory groupsin ustomizing&.

SNP Optimization Profile (n this profile, you specify the linear programming method to be used andthe constraints to be considered during the Optimization run.

SNP ost Profile (n this profile, you specify the weight given to different categories of costs inthe ob6ective function.

)ot Size Profile$transportation lanes&

(n this profile, you specify the minimum and ma%imum volume, weight, andpallet limits. -ou also specify the pull)in hori1on, which indicates the numberof days prior to the actual due date the system can fulfill reuirements inorder to fill the transport vehicle to at least the minimum level. Also used todetermine rounding values for discretization of lot sizes.

SNP Optimization *oundProfile

(n this profile $if you want to run a new SNP optimizer planning run&, you canlimit possible decision variable discrepancies from the last optimization runto increase planning stability. -ou can, for e%ample, permit smalldiscrepancies at the start of the planning period, and spread these over tothe end of the horizon, in order to avoid too many short#term planningalterations.

-our new plan does not have to be based on the directly precedingoptimization run, you can also choose earlier runs.

-ou can also maintain the SNP optimizer profile, the SNP cost profile, and the SNPoptimization bound profile in (nteractive Planning from Supply Network Planning.

SAP APO"7

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 28/31

A'ance !acros

5se

/se advanced macros to perform comple% calculations uickly and easily.

2acros are e%ecuted either directly by the user or automatically at a predefined point in time.

!he definition of macros is optional.

!he macros for aggregation and disaggregation come predefined with the system. -ou do nothave to write them yourself. Some stock level and days supply macros are also delivered with thestandard SNP planning books. -ou can create your own planning book for SNP using one of the e%istingbooks as a template, and copy the standard macros to the new book.

Integration

-ou create an advanced macro either when creating or chaning a planning book in ustomizing,or in design mode of interactive planning. -ou can define a macro either for an entire planning book or for a specific data view.

Prere*uisites9. -ou have created a planning area.;. -ou have created a planning buckets profile.?. -ou have created a planning book with at least one data view.

Features-ou can4

• ontrol how macro steps are processed through control instructions and conditions.• *uild a macro consisting of one or more steps.

• ontrol how macro results are calculated through control instructions and conditions.

• /se a wide range of functions and operators $see 79 1elp&.

• +efine offsets so that, for e%ample, the result in one period is determined by a value in theprevious period.

• :estrict the horizon in which the macro is e%ecuted to a specific period or periods.

• 'rite macro results to either a row, or a column, or a cell.

• 'rite the results of one macro step to a row, column, cell or variable, and use them only insubseuent iterations, macro steps or macros.

• !rigger an alert in the Alert 2onitor showing the outcome of a macro e%ecution.

!o create authorizations for the creation and e%ecution of macros, choose Tools →

Administration → ;ser 0aintenan#e → .oles from the SAP 3asy Access menu.

SAP APO"*

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 29/31

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 30/31

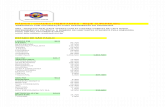

!he Optimizer icon is displayed on the interactive desktop automatically if you are using thestandard SNP planning book SNP@. 1owever, (f you create your own planning books, and wishto use the optimizer in interactive planning, you must specify that this icon should be displayed.-ou do this in the Design mode of the interactive planning desktop.

. On the 'onfiguration tab in the SNP Optimi1er window, you can choose one of your predefinedoptimization profiles, cost profiles, and optimization bound profiles. -ou can branch to themaintenance screens for the optimization profile and the optimization bound profiles, for e%ample,to make changes to e%isting profiles.

7or the cost profile, a pie chart with weight controls and a legend is displayed for all the relevantcost multipliers. !he cost multipliers to the left of the pie chart are highlighted in the color corresponding to the area on the pie chart where it is represented. !o access the field help $79&for each cost multiplier, simply choose one.

-ou can manually ad6ust the weights given to each cost multiplier by placing your cursor on a

relevant weight control, clicking the left mouse button, and moving your cursor up or down,depending on how you want to ad6ust the weight. !he corresponding area in the pie chart changessimultaneously as you ad6ust the weight.

9<. hoose E8e#ute to start the optimization run.

SAP APO3-

7/25/2019 Treinamento_SNP

http://slidepdf.com/reader/full/treinamentosnp 31/31

!he steps in the optimization process are displayed in the area on the far right side of the SNP Optimi1er window. 2essages about the run are displayed in the area below this. -ou can click ona message to display a longer e%planation.

(n addition, you can display the products that were selected for this optimization run by choosingProdu#ts. hoose Display log file, to branch to the Supply Network Planning7 Optimi1er Log <ilescreen. 7rom there, you can decide which type5form of log to display $for e%ample, the messagelog, input log, or results in te%t file, and so on.&

99. hoose the Solutions tab, to view the resulting costs associated with the solution from theoptimization run.