2519680_6003_ENG_B_W

-

Upload

sergioaldo -

Category

Documents

-

view

218 -

download

0

Transcript of 2519680_6003_ENG_B_W

-

7/28/2019 2519680_6003_ENG_B_W

1/4

Application Note

For the most, part industrial and com-

mercial electrical systems are getting

safer and more reliable. The U.S. Fire

Administrations most recent report,

analyzing data from 2001, estimates

that 8.7 % of the nations 47,785

non-residential fires were causedby electrical distribution equipment.

Thats 32 % fewer than in 1998.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

so a good testing program candeliver all three. In fact, manyindustrial insurance companiesrequire evidence of a regularelectrical testing program.

This article reviews the fun-damental causes of overheating,as well as the tests and toolscommonly used to uncover over-heating problems.

Strict building codes, high-qualityequipment, good system design,competent installation and pro-fessional maintenance are allfactors in driving the downwardtrend. Still, this translates to4,157 commercial, industrial andinstitutional buildings struck byelectrical fires in 2001.

Commercial, low-voltage sys-tems contain many sub-systems:switchgear, transformers, panels,receptacles, motor controls andlighting, to name a few. Commonto all of these components areconnections, insulation and over-current protection. Failures ofthese fundamental mechanismsare at the root of many electricalfires and are the target of manyelectrical maintenance proce-dures.

NETA Maintenance TestingSpecifications and NFPA standard70B Recommended Practice forElectrical Equipment Maintenancelist procedures for testing thevarious components of anelectrical distribution system.Thermographic testing is cov-ered by ASTM E 1934 StandardGuide for Examining Electricaland Mechanical Equipment withInfrared Thermography.

Many of the tests aimed atpreventing electrical fires alsoaddress reliability and safety,

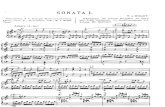

Use thermal imagers to check energized components for hot, loose or corroded connections.

Thermal image of a loose terminal contact.

Tests andmeasurements

for electrical

fire prevention

-

7/28/2019 2519680_6003_ENG_B_W

2/4

2 Fluke Corporation Tests and measurements for electrical fire prevention

Root causes of overheat-ing in electrical systems

Combustion requires both heatand fuel. Designers of electricalequipment are careful to use fire-resistant materials, making theelectrical system a poor providerof fuel. The fuel for the fire usu-ally comes from some nearbymaterial, with the electrical sys-tem providing the heat requiredfor ignition.

Heat is a normal byproduct ofthe flow of electric current. TheNational Electrical Code (NEC)takes heat into account and pro-vides rules for building a safeelectrical system. So how canan electrical system that wasdesigned and built to complywith the NEC still cause a fire?

Poor connections. Vibrationor thermal stress can cause con-nections in power distributionsystems to loosen. Contaminationcan corrode connections. Bothfactors increase the resistanceof the connection. All terminalsand splices are potential candi-dates for overheating, althoughthe more current a connectioncarries, the more critical it is to

maintain low resistance. Considerthat if a connector in a 50 ampsystem presents just 0.1 ohmsof resistance, it will dissipate250 watts at the interface of theconnection! Furthermore, if thecondition is allowed to persist,oxides will build up on the con-nection interface, causing theresistance to increase. Ultimatelythis can result in what is called aglowing connection, which cangenerate significant heat withouttripping protection devices.

Loose connections that peri-odically make and break canalso cause series arcs. Arcs areelectrical discharges across anair gap. In this case the arc is

generated across the small gapbetween conductors as the con-nection opens repeatedly. Theresulting heat is very focused andmay lead to insulation failure orfire if a combustible fuel source isnearby.

Switches, relays and circuitbreakers are also forms of con-nection. They are designed toopen and close repeatedly with-out overheating, but they aresubject to the influence of vibra-tion, heat, and contamination just

as any other connection.Insulation failure. One of the

reasons that electrical fires areless common is that the qualityof insulation is better than in thepast. But any insulation systemwill still degrade with age, heatand contamination.

The most extreme form ofinsulation failure is a short circuit.In this case, two conductors makecontact and remain in contact.The resulting overcurrent shouldcause a fuse or circuit breaker

to open. But if the overcurrentprotection device fails to open,the circuit upstream of the shortcircuit will be subject to over-heating.

If theres a ground fault (ashort circuit involving an equip-ment ground), then the breakershould also open. If it doesnt,the same overheating arises. Iftheres a resistive connection inthe bonding system that limitsthe current, the resulting currentmay not be sufficient to trip the

upstream protection devices butmay still cause heating in thebonding system.

Parallel arcing occurs whentwo connectors come close, or

touch and part. It has similarcharacteristics to series arc-ing (above) but tends to involvehigher currents. This can causeignition of a nearby fuel sourceor further degradation of theinsulation. Arcing can dischargehot metal sparks that can ignite anearby fuel source.

If insulation is subjected to theheat of other failures, the surfaceof the insulation can char andbecome conductive. A phenome-non called arc tracking can result,

causing intense localized heatingsimilar to other arcing.Lightning. One of the func-

tions of the ground system is toprovide a low impedance path toearth, allowing a lightning striketo pass with as little damage aspossible. Surge suppressors relyon a good ground path to operateeffectively. Periodic testing of theground system and the resistancebetween the ground electrodeand earth helps to insure thatthis system will work when it

needs to.Harmonics. Most of the cur-rent that flows in a US electricalsystem cycles at 60 Hz. Harmoniccurrents contain higher frequencycomponents that generate heatthroughout the system. Harmonicdistortion is present in anyelectrical system that supplieselectronic loads like motor drives,computers, control systems orproduction machines. Extremedistortion and heavy loading cancause overheating in electrical

equipment, especially in olderdistribution systems.The 3rd harmonic is caused by

single-phase loads like computersand other office machines. Thisharmonic adds in the neutral ina three-phase system and cancause the neutral conductor tooverheat if it is too small.

Avoid electrical shorts by testing the insulation resistance on cabling.

-

7/28/2019 2519680_6003_ENG_B_W

3/4

3 Fluke Corporation Tests and measurements for electrical fire prevention

Overloading. If a load drawstoo much current, the systemcomponents upstream of the loadhave to carry that current. The

main protection against overloadis the overcurrent protectiondevice which should open. If itdoes not open, the high currentwill cause overheating distributedalong the portion of the systemupstream of the excessive load.

Wiring mistakes. The elec-trical system in commercialbuildings is a dynamic entity.Over time, tenants change, pro-duction lines move, and newequipment gets installed. In atime crunch, mistakes are com-

mon and although a system mayoperate just fine for a while,latent problems can be created.

A potential fire hazard existswhen someone upsizes a pro-tection device without changingthe wire size. For example, sim-ply replacing a 20 amp circuitbreaker with a 30 amp circuitbreaker could allow existing 12AWG wiring to carry excessivecurrent. A similar situation occursany time someone connects asmaller gauge wire to a circuit

with higher ampacity.

Using one neutral conductoras a return path for more thanone phase conductor will enableloads to function but can eas-

ily overheat the shared neutralconductor.

Tests and measurementsfor detecting heat andfailing components

The trick with detecting electricalfire hazards is knowing what anabnormal reading looks like. Thebest solution is to gather baselinereadings for especially importantcomponents and equipment. Thatgives you a point of comparison.Then, make a habit of performing

these tests once a year. That willspot other kinds of failures in theworks, yielding predictive main-tenance cost savings as well asfire prevention.

Here are the most commontools and measurements thattesting professionals use to checkfor overheating or an inclinationtowards overheating.

Visual inspection. Electricitymay be invisible, but the effectsof heating on metal and insula-tors are not. Discoloration orcharring is a sure sign that com-

ponents are overheating. Also bealert for smells, like an overheat-ing component would produce.

Thermography. Thermalimagers can read the infraredenergy emitted by an objectand create a visible image ofthe objects surface temperature.Hot, loose connectors show updramatically on these thermalpictures, especially in comparisonto cooler, tight connections. Thisnon-contact technique is perfectfor checking energized compo-

nents and scanning operationalequipment, but it cant measureconcealed (thermally-insulated)insulation or connections.Likewise, electrical panels mustbe open for the imager to mea-sure the components. FollowNFPA 70E safety procedures andwear appropriate personal pro-tective equipment (PPE) in theseinstances.

Connection/switch resis-tance. Another method forchecking connectors is by electri-

cally measuring the resistance ofthe connection. On an energizedsystem, a resistive connection willcause a measurable voltage dropacross the connection. A precise,properly rated handheld volt-meter will do the job. However,this test does involve probing anenergized system, so safety isa concern. The technician mustclosely follow PPE requirementsand OSHA protocols.

On a de-energized system,using a micro-ohmmeter will pro-

duce much more accurate results.This tool applies a dc current of10 amps or more through a con-nector and precisely measuresthe voltage drop. This test showsthe resistance of a connectiondown to a fraction of a micro-ohm, insuring that the connectionwill not dissipate excessive heator, identifying connectors thatcould be hazardous.

Periodically examine power quality for voltage sags, harmonics and other causes ofoverheating.

-

7/28/2019 2519680_6003_ENG_B_W

4/4

4 Fluke Corporation Tests and measurements for electrical fire prevention

Insulation testing. Insulationresistance is measured betweenphase conductors and betweenphase conductors and groundconductors. Good insulation

should have very high resis-tance. An insulation testerapplies a high dc voltage to de-energized, isolated components.The instrument then measuresthe resistance between the twopoints. This testing can be usedto check large segments of insu-lation, including long lengths ofcable, transformer windings, andmotor windings. Low insulationresistance readings can indicatethat somewhere on that lengththe cable is breaking down,

potentially causing a short.

Ground resistance testing.Periodic ground measurementscan help make sure lightningdamage is minimized in theevent of a strike. Obviously

the need is more urgent ifyou are responsible for facili-ties in lightning-prone areas. Aground resistance test is usu-ally performed during a systemshutdown, because the groundelectrode must be disconnectedtemporarily.

Transformer turns ratio.Insulation failure inside trans-formers can result in shortedturns, potentially reducing thenumber of turns on the effectedside. A transformer with shorted

turns is prone to overheating. Youcan check the ratio on a low volt-age transformer by isolating thesecondary from loads and using avoltmeter to compare the primaryvoltage to the secondary volt-age. A more accurate approachis to use a special transformer-winding test set, which willgive a precise ratio as well asa good picture of the magneticcharacteristics.

Circuit Breaker Testing.Circuit breakers are the keyto electrical fire prevention.Proper testing of circuit breakersrequires special equipment and

specialized expertise. Testingis performed with the breakerremoved from the circuit and thetests verify the trip current anddelay.

Power Quality Measure-ments. Power quality studies canuncover symptoms that signalpotential overheating. Periodicallymeasuring harmonic distortionwill alert you to potential heat-ing problems due to excessiveharmonic current. Voltage sagscan be viewed as annoyance,

but in systems service, they maybe caused by deteriorating con-nections. Many wiring problemsbecome apparent during a com-prehensive power quality study.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.Fluke Europe B.V.PO Box 1186, 5602 BDEindhoven, The Netherlands

For more information call:In the U.S.A. (800) 443-5853 orFax (425) 446-5116In Europe/M-East/Africa +31 (0) 40 2675 200 orFax +31 (0) 40 2675 222In Canada (800)-36-FLUKE orFax (905) 890-6866From other countries +1 (425) 446-5500 orFax +1 (425) 446-5116Web access: http://www.fluke.com

2005-2009 Fluke Corporation.Specifications subject to change without notice.Printed in U.S.A. 5/2009 2519680 A-EN-N Rev B

Modification of this document is not permittedwithout written permission from Fluke Corporation.

Fluke. Keeping your worldup and running.